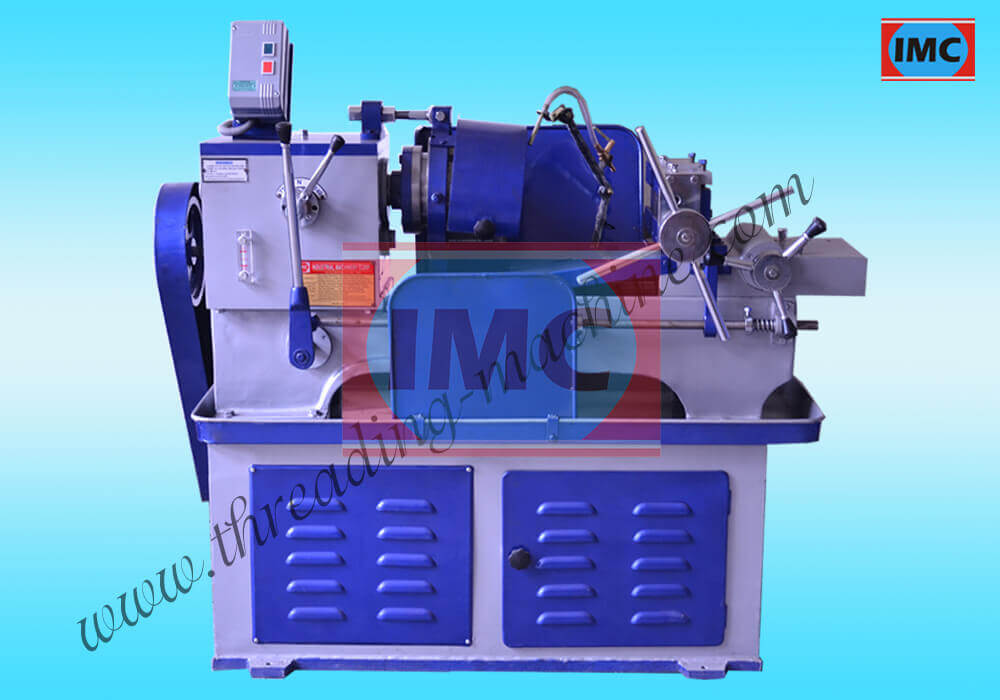

Pipe Threading Machine

Industrial Machinery Corporation has become a very familiar name in the world of industrial machine manufacturers owing to its continuous hard work and supplying best quality industrial machines to ou ...

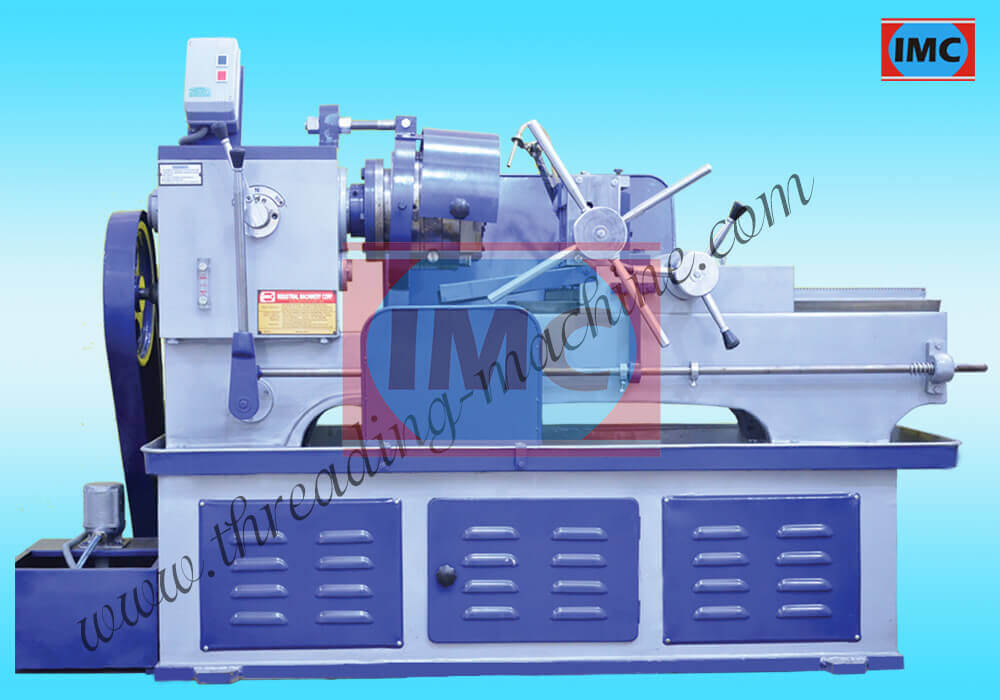

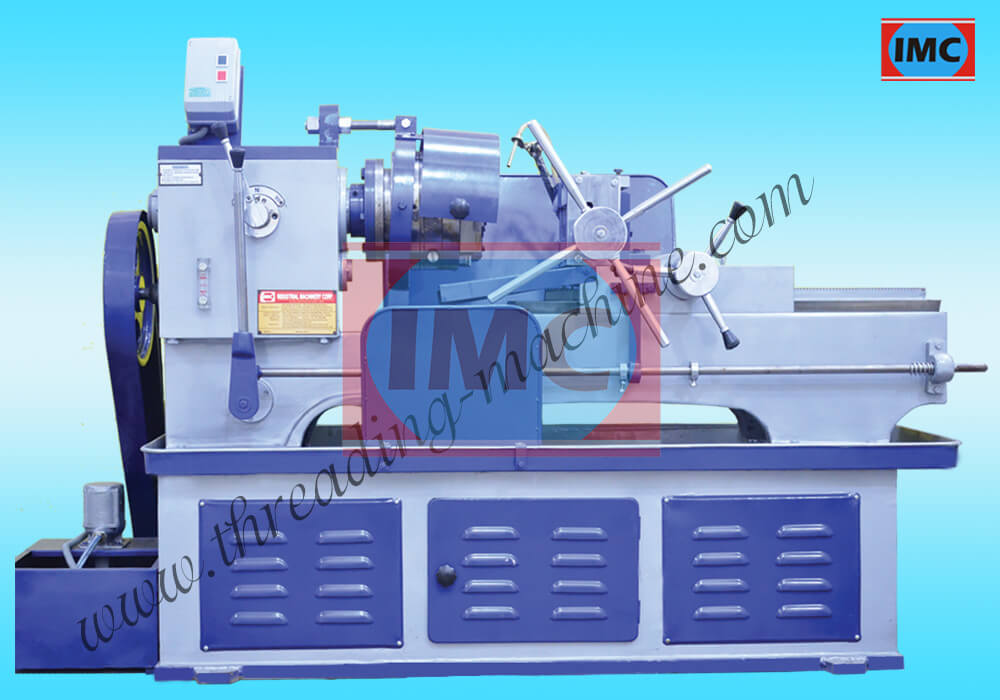

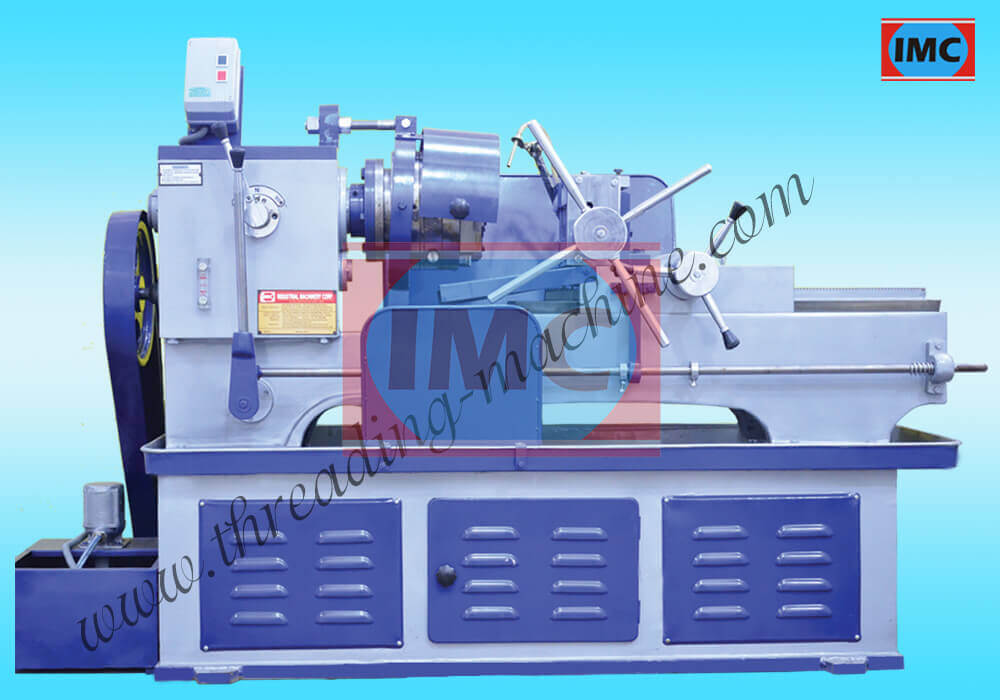

VIEW MOREFor many years Bar Thread Cutting Machine has been the best and most used machine for all bar thread cutting and related purposes. Bar Thread Cutting Machine has lived up to the reputation of being the best Bar Threader by giving the most accurate and précised thread cutting outcomes. Bar Threader manufactured at industrial machinery corporation has been famous for their robustness, and design, and for producing the best quality results even while working in the harshest working conditions. The best part about Our machinery is that despite having so many qualities, this machinery does not burn the pockets of the buyers and once bought machines are ready to work for several years without actually asking for maintenance these machines are also proven for their low maintenance cost.

VIEW SPECIFICATIONSFor many years Bar Thread Cutting Machine has been the best and most used machinery for all bar threaders and related purposes. Bar Threader has lived up to the reputation of being the best Bar Thread Cutting Machine by giving the most accurate and précised thread cutting outcomes. Bar Threader manufactured at industrial machinery corporation has been famous for its robustness, design, and producing the best quality results even while working in the harshest working conditions. The best part about the Bar Thread Cutting Machine is that despite having so many qualities, this machinery does not burn the pockets of the buyers also once bought this machinery is ready to work for several years without actually asking for maintenance so this machine is also a proven one for its low maintenance cost.

A Round Bar Thread cutting Machine is used in factories and tool rooms to cut an external thread on the bars and this machinery functions on the chasing method where the rod is made to stay unmoved at one place and make the die head rotate around it to produce superfine threads on the bar. HSS tangential chasers are deployed in a Round Bar Threader for thread cutting purposes and this machinery is capable of cutting various varieties of threads. However, this variety would come depending on the type of chaser that is being used at that time. Generally, a Rebar Threader can draw the following type of threads on bars:-

The Bar Threader made by us at our Ludhiana-based unit has made us get the tag of being the best Bar Thread Cutting Machines Manufacturers. The reason why this has happened is that for almost a decade we have been making the Bar Threader with utmost love and full care that no defective raw material is used to make these machines. Over these ten years of being in business, we are fully aware of all the techniques and latest technology prevailing in the market, which could enhance the working ability of our Machinery. All the gears and levers of our Machinery have an extra large face for better gripping while operating and all are made up using the highest quality steel as raw material. Our Rebar Threader has an extra fine cut on the hobbing which makes it confirms that the machinery will not create excess noise while operating at its fullest speed. Listed below are the names of various parts of a Bar Thread cutting Machine:-

We understand that the overall working ability and strength of the machinery lies in its body, hence we make sure that only the best quality raw material is used to make our Thread Cutting Machine. We have a dedicated quality checking team, whose main task to keep a strict vigil on the quality of raw material coming in. they have been given full authority to reject the raw material even with a tinge of defect or fault in it.

Specifications:| MODEL | 1/4" TO 1" (BED TYPE) | 3/8" TO 1.1/2" (BED TYPE) | 1/2" TO 2.1/2" (BED TYPE) |

| Saddle Movement | 10" | 13" | 22" |

| Spindle Speed Range | 75-140 | 75 -140 | 45 - 90 |

| Number of Spindle Speed | 2 | 2 | 2 |

| Threading Capacity | 1/4" to 1" | 3/8" to 1.1/2" | 1/2" to 2.1/2" |

| Production per Hour | 60-80 | 60-80 | 70-90 |

| H.P. Required | 3 H.P. | 3 H.P. | 7.5 H.P. |

| Lead Screw | Optional | Optional | Optional |

| Weight (KG) Approx. | 500 | 550 | 990 |

Bar Thread Cutting Machine Tangential Chaser

IMC Tangential Chasers are manufactured from imported High-Speed Steel which must pass exacting metallurgical standards. Experienced heat treatment with the automatically imported heat treatment plant and imported Testing equipment, assure that they will perform satisfactorily in service and produce quality threads within the tolerance for which they were intended. These Tangential Chasers are used in Bar Thread Cutting Machines.

IMC Chaser is interchangeable. If one Pc. Of a chaser, the set is damaged & is beyond use. The same No. pc. Of the other chaser set lying in stock may be used and there will not be any difference in thread cutting performance and the damaged set can be replaced without the necessity of replacing the entire set.

Read More...

Industrial Machinery Corporation has become a very familiar name in the world of industrial machine manufacturers owing to its continuous hard work and supplying best quality industrial machines to ou ...

VIEW MORE

In a very short span of time, Industrial Machinery Corporation has been named among the best bolt threading machine manufacturers and suppliers from India. The main reason behind that is our continuou ...

VIEW MORE

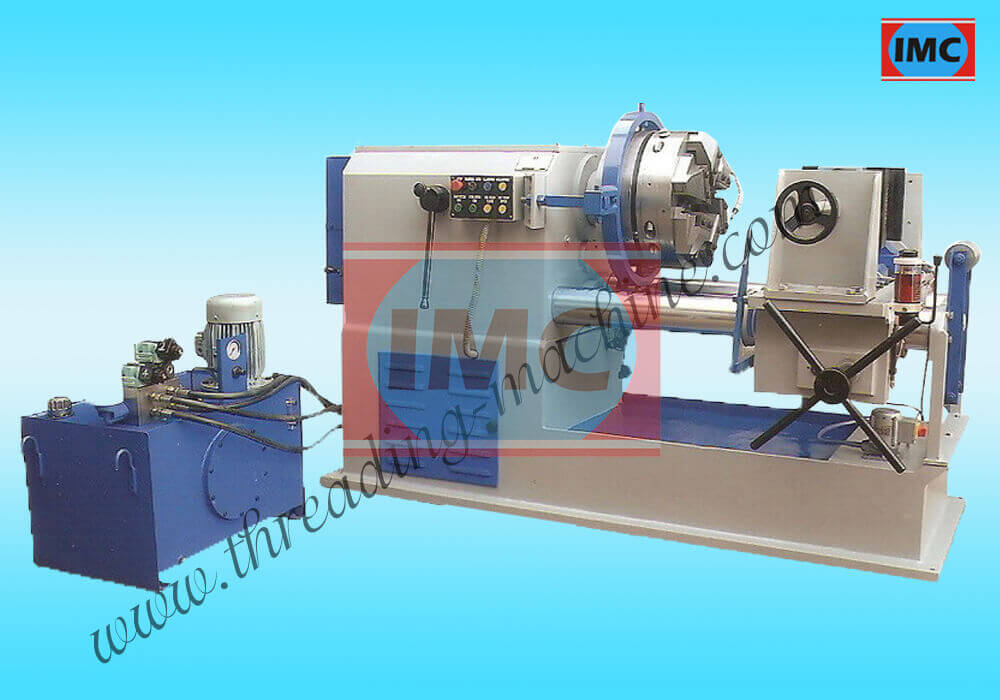

Industrial Machinery Corporation has been in this business of manufacturing and supplying Hydraulic Pipe Threading Machine for more than a decade now. For all these seven years, we have been researchi ...

VIEW MORE

Rod Threading Machine is a machine that we take pleasure in describing. It is perhaps the best crafted and artistically designed at industrial machinery corporation factory at Ludhiana. We have been i ...

VIEW MORE

We have the wide range of semi-automatic Steel TMT Chaser Rebar Threading Machine which is used for the site projects and it does outside threading on TMT bars. Steel TMT Chaser Rebar Threading Machin ...

VIEW MORE

Electric Conduit Pipe Threading Machine is used to thread the external area of the conduit pipes. IMC Machines highly specialized and can be used solely for industry-specific purposes. There are only ...

VIEW MORE