Our Flat die thread rolling machines allows the production of large and small batches of all kinds of threads that can be cold formed, in the most economically way.

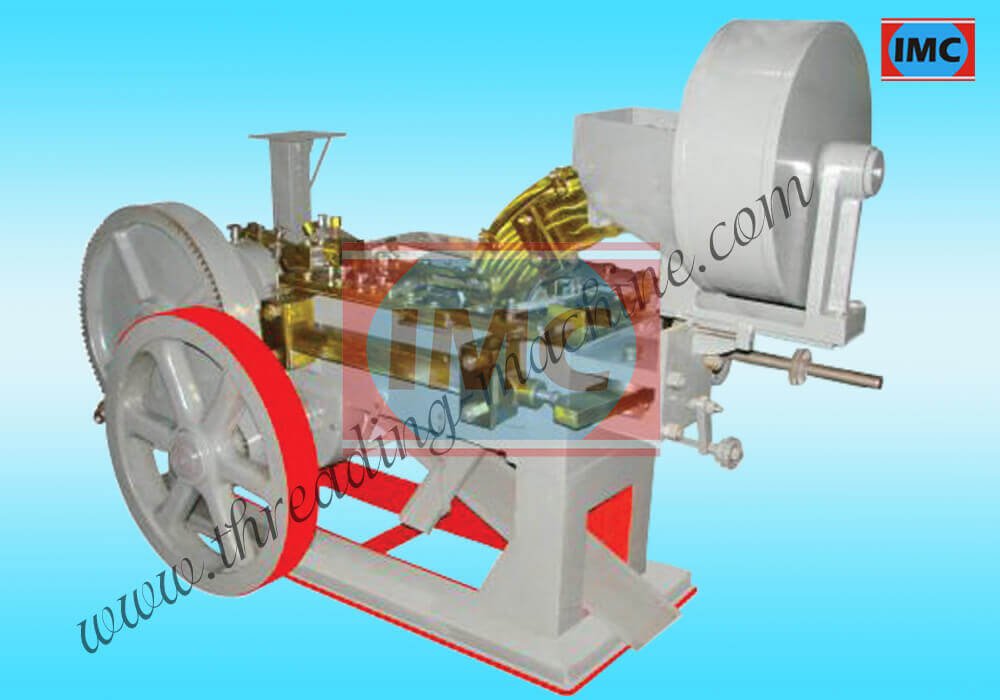

The IMC Automatic Cold Thread Rolling Machine is an advanced and versatile solution designed to streamline and automate the process of creating threads on metal rods, bolts, and other cylindrical components. This machine utilizes cold rolling technology to efficiently and accurately form threads, offering numerous benefits over traditional thread-cutting methods.

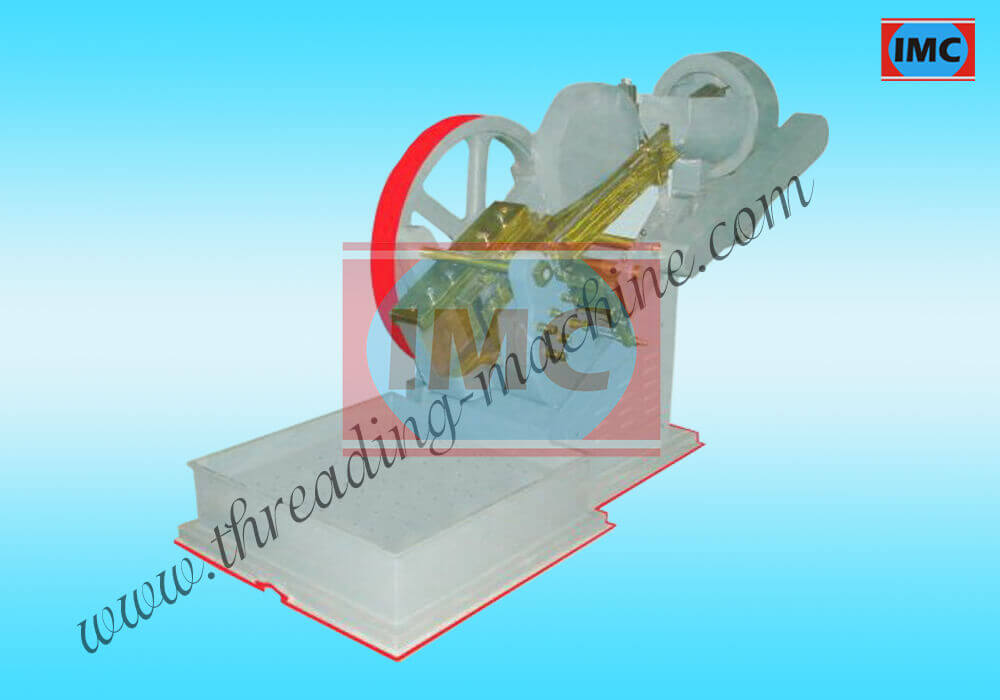

Cold thread rolling is a process in which threads are formed by applying pressure to the workpiece using hardened steel dies. Unlike thread cutting, which removes material to create the desired thread, cold rolling displaces the metal without cutting, resulting in stronger and more precise threads. This method enhances the structural integrity of the threaded components, making them highly resistant to fatigue and ensuring a reliable connection.

The IMC Automatic Cold Thread Rolling Machine is equipped with advanced features to optimize the thread rolling process. It is designed for high-speed operation, allowing for efficient production and increased productivity. The machine's automatic feeding and ejection systems facilitate continuous operation, minimizing downtime and maximizing output.

One of the key advantages of the IMC Automatic Cold Thread Rolling Machine is its versatility. It can handle a wide range of workpiece sizes and thread specifications, making it suitable for various applications across industries such as automotive, aerospace, construction, and manufacturing. The machine can produce both internal and external threads, offering flexibility in meeting specific project requirements.

The user-friendly interface and intuitive controls of the machine ensure ease of operation and quick setup. Operators can easily adjust the thread parameters, such as pitch, diameter, and length, to achieve the desired results. Additionally, the machine is equipped with safety features to protect the operator and prevent accidents.

By automating the thread rolling process, the IMC Automatic Cold Thread Rolling Machine significantly reduces labor costs and improves efficiency. It eliminates the need for manual threading operations, which are time-consuming and often prone to errors. The consistent and precise threads produced by the machine contribute to enhanced product quality and reliability.

In conclusion, the IMC Automatic Cold Thread Rolling Machine is a state-of-the-art solution that revolutionizes the process of creating threads on metal rods and bolts. Its cold rolling technology, versatility, high-speed operation, and user-friendly design make it an indispensable tool for industries that require strong and reliable threaded components. With this machine, manufacturers can achieve increased productivity, improved product quality, and cost savings in their thread production processes.

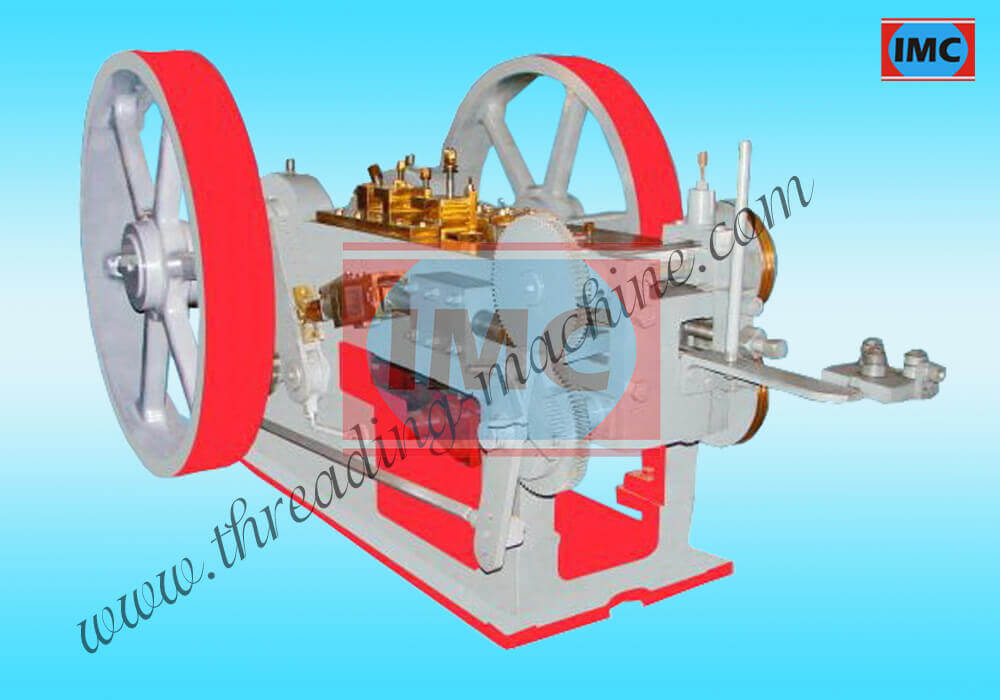

Specifications:

| Model No. | FDTRM-1 | FDTRM-2 | FDTRM-3 | FDTRM-4 | FDTRM-5 | FDTRM-6 | FDTRM-7 |

| Min. Max. Dia Can Be Rolled | 1/16"x1/4" | 1/8"x3/8" | 1/8"x1/2" | 1/4"x5/8" | 1/4"x3/4" | 1/4"x7/8" | 3/8"x1" |

| Max. Length of Thread | 2" | 2.1/2" | 3" | 3" | 4" | 4" | 4" |

| Dimension of Fixed Dia | 3"x2"x1" | 5"x2.1/2"x1" | 5"x3"x1" | 6"x3"x1" | 6"x4"x1" | 7"x4"x1" | 8"x4"x1.1/2" |

| Dimension of Moving Dia | 4"x2"x1" | 6"x2.1/2"x1" | 6"x3"x1" | 7"x3"x1" | 7"x4"x1" | 8"x4"x1" | 9"x4"x1.1/2" |

| Production in Pieces Per Minute | 80 | 60 | 60 | 50 | 30 | 30 | 20 |

| Power Required in H.P. | 2 | 3 | 5 | 7.5 | 10 | 15 | 20 |