Mig Welding Machine

Being in the business of welding machine producing for over 7 years, what we would advise all of the purchasers with respect to MIG Welding Machine is to have a point by point discussion on what are t ...

VIEW MOREFounded in the year 2011 at Ludhiana, Punjab, India, we “Industrial Machinery Corporation” are manufacturing and exporting a qualitative of Welding Machines, Scaffolding Welding Fixtures, Welding Machinery, Welding Equipment and Special Purpose Welding Machine. These products are manufactured using the best quality raw material, components, and cutting-edge technology as per the set industry standards. These products are well-known for features like corrosion resistance, durability, low maintenance, hassle-free operation and long life. We export these products to all over the world. Our organization is supervised by, “Mr. Davinder Jit Singh” (CEO), who has immense industry experience. We are offering our products under reputed brands like IMC.

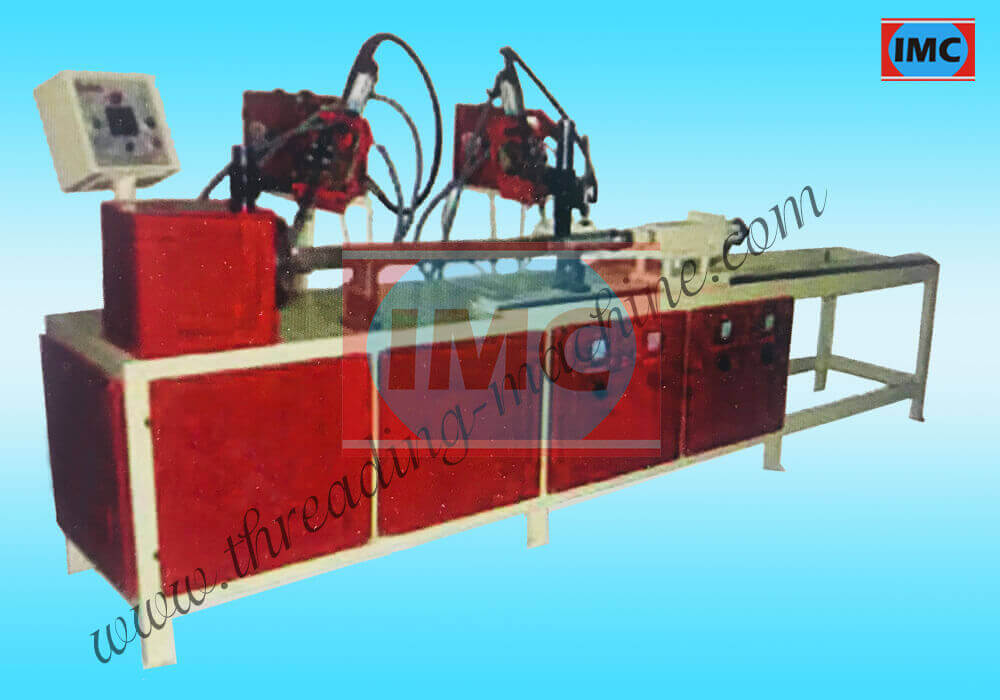

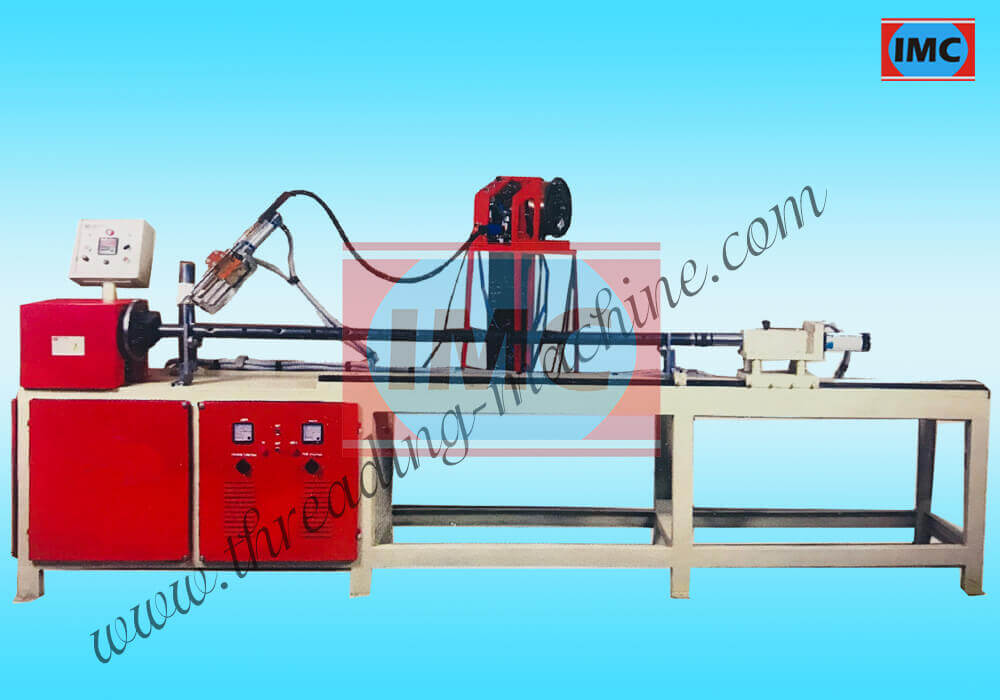

VIEW SPECIFICATIONSIn the construction industry, stability and safety are paramount. Scaffolding systems play a vital role in providing support and stability to workers. One essential component of scaffolding is the base jack, which ensures a solid foundation. IMC (Industrial Machinery Corporation) has introduced an innovative solution to enhance the production and repair process of base jacks through their cutting-edge Base Jack Welding Machine. This article explores the features and benefits of the IMC Base Jack Welding Machine and its potential impact on the construction industry.

Streamlined Welding Process:

The IMC Base Jack Welding Machine offers a streamlined and efficient welding process specifically designed for base jack production or repair. With this machine, construction companies can save time and labor costs by welding base jacks in-house rather than outsourcing the task. The machine provides a controlled environment for welding, ensuring consistent and high-quality welds every time.

Advanced Welding Technology:

Equipped with advanced welding technology, the IMC Base Jack Welding Machine offers versatility and precision. It supports various welding methods, including Shielded Metal Arc Welding (SMAW) and Metal Inert Gas (MIG) welding, allowing users to choose the most suitable method for their specific needs. The machine incorporates state-of-the-art welding controls, enabling operators to adjust welding parameters such as voltage, current, and wire feed speed, ensuring optimal results for different base jack materials and dimensions.

Robust Construction and Safety Features:

IMC prioritizes both durability and operator safety. The Base Jack Welding Machine is constructed with robust materials to withstand heavy-duty usage in demanding construction environments. Safety features such as heat shields, emergency stop buttons, and protective covers are integrated into the machine design, ensuring a secure and accident-free welding operation.

Customization and Adaptability:

IMC understands that construction projects have unique requirements. The Base Jack Welding Machine offers customization options to meet specific customer needs. It can be adapted to accommodate various base jack sizes, ensuring compatibility with different scaffolding systems and enabling seamless integration into existing production processes.

Increased Productivity and Cost Savings:

By investing in the IMC Base Jack Welding Machine, construction companies can experience significant benefits. The ability to weld base jacks in-house reduces lead times, minimizes transportation costs, and allows for better quality control. With increased productivity and cost savings, companies can improve their bottom line and gain a competitive edge in the market.

The IMC Base Jack Welding Machine represents a significant advancement in the construction industry, specifically in the production and repair of base jacks. With its streamlined welding process, advanced technology, robust construction, and safety features, this machine offers enhanced efficiency and quality. By incorporating the IMC Base Jack Welding Machine into their operations, construction companies can optimize productivity, reduce costs, and ensure the stability and safety of their scaffolding systems. IMC continues to demonstrate its commitment to innovation and providing practical solutions that meet the evolving needs of the construction industry.

| Electric Supply | Single Phase 220 + - 10 % Volts Frequency HZ 50/60 | ||

| Speed | 2 to 10 RPM | ||

| Motor Drive | 75 C | ||

| Motor Type | DC | ||

| Torch Clamping | PNEUMATIC | ||

| Length Adjustment | Up to 1000 mm | ||

| Dimension | L x W x H 5.4x2.5x4.7 (Foot) |

Being in the business of welding machine producing for over 7 years, what we would advise all of the purchasers with respect to MIG Welding Machine is to have a point by point discussion on what are t ...

VIEW MORE

Founded in the year 2011 at Ludhiana, Punjab, India. we “Industrial Machinery Corporation” are manufacturing and exporting a qualitative of Welding Machines, Scaffolding Welding Fixtures, Welding ...

VIEW MORE

Automatic Inner prop welding machine is used to weld base plate with a pipe without making any joint between them, It gives high production and accuracy to the product. Inner prop is used with a combi ...

VIEW MORE

Industrial Machinery Corporation got incorporated in the year 2011 in Ludhiana, Punjab, India. A decade-long business journey has helped us to earn a reputable position in the market and we are a lead ...

VIEW MORE

Industrial Machinery Corporation has gained a huge name as an expert in manufacturing Cups and lock pins Tagging Machines and this is true too, as we truly have the best team and set-up to manufacture ...

VIEW MORE

The name of Industrial Machinery Corporation is ranked in top ten manufacturers and exporters of welding machines owing to its best quality welding machinery that we have manufactured which are popula ...

VIEW MORE

Are you in need of a cutting-edge solution for punching holes in scaffolding pipes? Look no further than IMC, a trusted manufacturer and exporter of construction machinery. Our Scaffolding Pipe Punchi ...

VIEW MORE

Are you seeking a reliable and high-performance welding solution for scaffolding prop nut cup handles?Look no further than IMC, a leading manufacturer and exporter of construction machinery. Our Scaf ...

VIEW MORE

Are you searching for an advanced welding solution for double-sided scaffolding prop production?Look no further than IMC, a renowned manufacturer and exporter of construction machinery. Our Double-Si ...

VIEW MORE

Are you in search of an advanced and automated solution for producing scaffolding cup sleeve nuts, handles, and G pins? Look no further than IMC, a leading manufacturer and exporter of construction ma ...

VIEW MORE