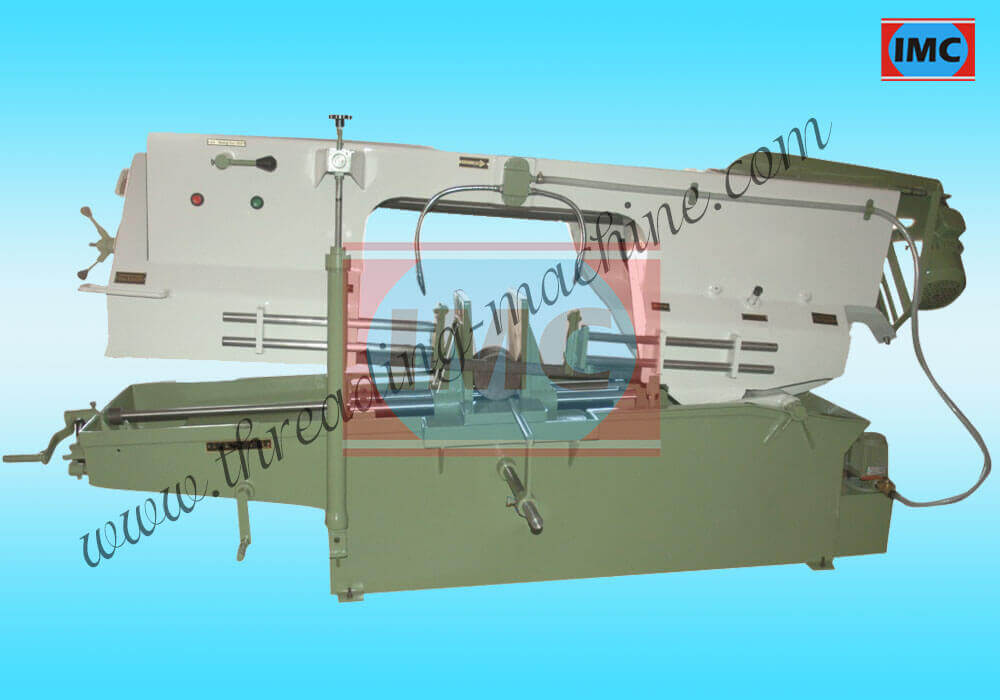

Bandsaw Machine

Welcome to the world of precision cutting with Industrial Machinery Corporation's Manual Bandsaw Machines. With a legacy spanning the last 12 years, we take pride in delivering top-notch quality and reliability to meet the diverse needs of industrial cutting applications. Our manual bandsaw machines are designed with precision engineering and user-friendly features, ensuring optimal performance and efficiency.

Tags

Bandsaw Machine, Bandsaw Machine Manufacturer, Bandsaw Machine Manufacturer Exporter, Bandsaw Machine Manufacturer, Exporter in India at Best Price, Industrial machinery, Industrial machinery Manufacturer in India, Machinery Exporter in India, India, Ludhiana Punjab IndiaAvailable Options

Specifications

Welcome to the world of precision cutting with Industrial Machinery Corporation's Manual Bandsaw Machines. With a legacy spanning the last 12 years, we take pride in delivering top-notch quality and reliability to meet the diverse needs of industrial cutting applications. Our manual bandsaw machines are designed with precision engineering and user-friendly features, ensuring optimal performance and efficiency.

Key Features:

Cutting Precision: Our Manual Bandsaw machines are crafted with a focus on precision cutting. The continuous loop of toothed metal ensures accurate and straight cuts in various materials, ranging from metals to wood.

Durability and Reliability: Industrial Machinery Corporation is committed to providing robust and durable machines. Our Manual Bandsaw machines are built with high-quality materials, ensuring longevity and consistent performance in demanding industrial environments.

Versatility: Designed to handle a wide range of materials, our bandsaw machines are versatile tools suitable for cutting metal, wood, plastic, and more. This adaptability makes them invaluable in various industries.

User-Friendly Operation: Operating our Manual Bandsaw machines is a breeze. With an intuitive interface, operators can easily control and manage the cutting process, ensuring efficiency and minimizing the learning curve.

Adjustable Blade Speed: Tailor the cutting speed to suit different materials with the adjustable blade speed feature. This versatility allows for optimal performance in various cutting applications.

Safety First: Your safety is our priority. Our bandsaw machines come equipped with essential safety features, including blade guards and emergency stops, ensuring a secure working environment for operators.

Steps for Operating Our Manual Bandsaw Machines:

Safety First: Before starting, conduct a thorough safety check, ensuring all safety guards are in place, and operators are equipped with appropriate personal protective gear.

Blade Installation: Install the bandsaw blade according to the provided guidelines, ensuring proper tension for optimal cutting performance.

Table Adjustment: Set the table at the desired height and angle for the specific cut. Our machines feature adjustable tables for flexibility in cutting different materials.

Blade Speed Setting: Adjust the blade speed based on the material being cut. Our machines offer customizable speed settings for enhanced efficiency.

Workpiece Securement: Use the vise or clamp to securely hold the workpiece in place on the table, preventing movement during the cutting process.

Machine Activation: Power on the bandsaw machine, allowing the blade to reach its full speed before initiating the cutting process.

Precise Cutting: Gently feed the workpiece into the rotating blade along the intended cutting line. Allow the blade to do the work, ensuring accuracy and efficiency.

Monitoring and Adjustments: Keep a close eye on the cutting process, making any necessary adjustments to the feed rate or other settings for optimal results.

Completion of Cut: Once the cut is complete, power off the machine and allow the blade to come to a complete stop before removing the cut material.

Routine Maintenance: Perform routine maintenance tasks, such as blade inspection, tension adjustment, and lubrication, to keep the bandsaw machine in optimal working condition.

At Industrial Machinery Corporation, we understand the importance of precision and reliability in your cutting processes. Our Manual Bandsaw machines are a testament to our commitment to delivering quality machinery that stands the test of time. Join the ranks of satisfied customers who have relied on our bandsaw machines for over a decade. Experience the difference with Industrial Machinery Corporation – where precision meets performance.

| Model (unit) | HM-175 | HM-200 | HM-250 | HM-300 | HM-350 | HM-400 | HM-450 |

| Capacity(mm) | 175mm | 200mm | 250mm | 300mm | 350mm | 400mm | 450mm |

| Round(mm) | 175mm | 200mm | 250mm | 300mm | 350mm | 400mm | 450mm |

| Square(mm) | 150x150 | 150x150 | 200x200 | 250x250 | 300x300 | 350x350 | 400x400 |

| Drive Motor (HP/ RPM) | 0.5/1440 | 1/1440 | 1.5/1440 | 2/1440 | 2/1440 | 2/1440 | 3/1440 |

| Coolant Pump (HP/ Volts) | 0.15/440 | 0.15/440 | 0.15/440 | 0.15/440 | 0.15/440 | 0.15/440 | 0.15/440 |

| Blade Speed (Meter / Minute) | 25/30/40 | 20/35/55/75 | 20/35/55/75 | 35/55/75 | 35/55/75 | 35/55/75 | 35/55/75 |

| Bandsaw Blade (mm) | 2515x19x0.9 | 3000x27x0.9 | 3000x27x0.9 | 3760x27x0.9 | 4100x27x0.9 | 4420x34x1.1 | 4700x34x1.1 |

| Floor Space LxWxH (mm) | 1500x570x870 | 1630x580x895 | 2000x600x900 | 2400x830x1050 | 2550x830x1050 | 2650x830x1200 | 2800x830x1250 |

| Net Weight (kg) approx. | 250 kg | 322 kg | 400 kg | 651 kg | 600 kg | 650 kg | 700 kg |

| Packed Weight (wooden) approx. | 330 kg | 400 kg | 500 kg | 731 kg | 800 kg | 850 kg | 910 kg |