Scaffolding Pipe Threading Machine

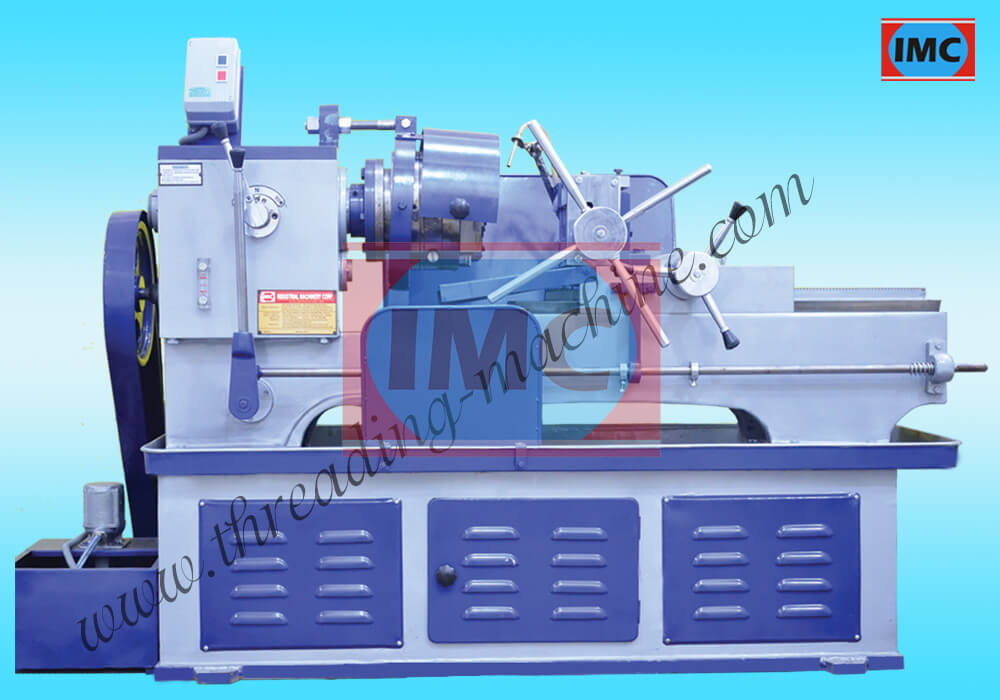

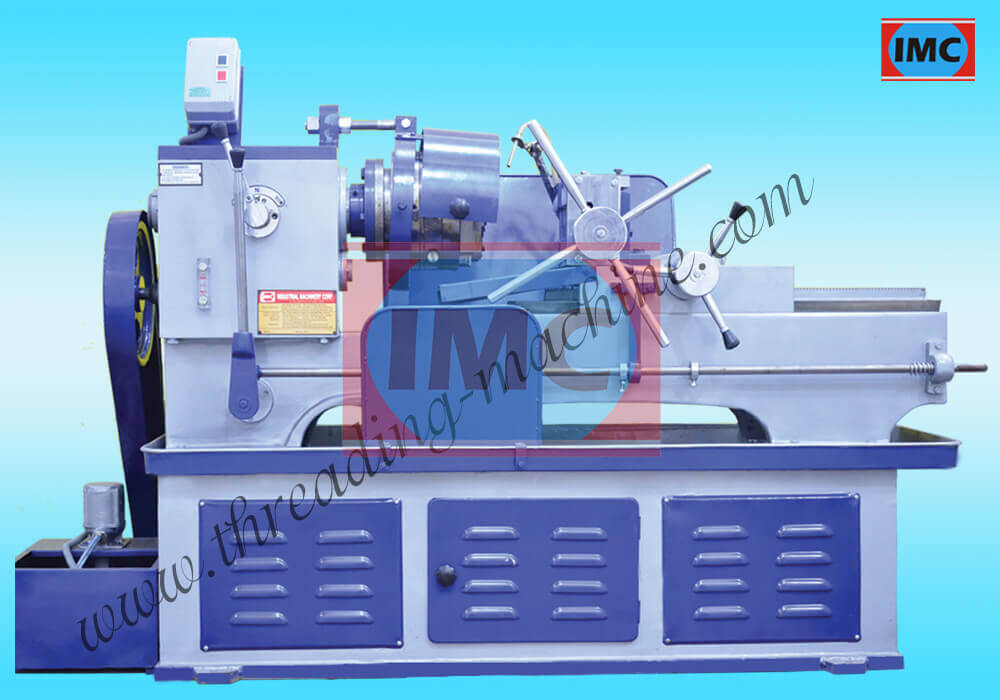

Ever since we have stepped into the business of industrial machines manufacturing, we have been performing consistently to produce high-quality industrial machines and satisfying our clients. All the expertise that we have accumulated over these years, we have applied in designing and manufacturing our Scaffolding Pipe Thread Cutting Machine. Our Scaffolding Pipe Thread Cutting Machine is considered as the best designed and manufactured Scaffolding Pipe Thread Cutting Machine. We are considered as the best company in the manufacturing of this machine as we have a special expertise in manufacturing Scaffolding Pipe Thread Cutting Machine having 3 rollers [HU-3R Rolling machine]. These scaffolding machines run using hydraulic principle. At our Ludhiana-based manufacturing unit, we have got some of the best technicians using the best technologies to manufacture these Scaffolding Pipe Thread Cutting Machines. This is the reason why our machine is the biggest show-stopper and was admired by entire industrial machine manufacturing industry. The designers of our Scaffolding Pipe Thread Cutting Machines are all having decades of international experience in designing various industrial designs and the technicians working with us work with so much dedication that they have manufactured this machine to be sturdy enough to work for long hours. The entire structure of our Scaffolding Pipe Thread Cutting Machine is set up in such a way that even after working continuously for long hours on its highest speed, this machine shows no signs of wear and tear or system failure. The operating buttons are very easy to understand and in fact, the entire machine is so easy to operate that after watching it how to operate for 15-20 minutes, any neophyte can learn operating it with perfection. While in manufacturing unit, our quality control team checks the raw material completely that is to be used in the manufacturing process of this machine and if any fault or defect is found, that part or piece of raw material is removed completely. No negotiations or compromises are made when it comes to maintaining the quality and robustness of our Scaffolding Pipe Thread Cutting Machine.

While manufacturing of these machines, each and every part is carefully joined with uttermost accuracy and carefulness to give the buyers, a Scaffolding Pipe Thread Cutting Machine that provides the most accurate and precise thread cutting while in operation. The Scaffolding Pipe Thread Cutting Machine that we build here is best to performing threading jobs like pipe rolling, lapping work, high-precision thread cutting and for high-level production of scaffolding pipe jack and solid jacks’ screws etc. Listed below are the names of thread cuts that this machine can cut.

- Matric

- BSP

- BSPT

- NPT

- UNF

- UNC

- BSW

- Acme Threads

- B.S.F

Listed below are the names of spare parts that are assembled together at our manufacturing unit at Ludhiana to make a Scaffolding Pipe Thread Cutting Machine.

- Base Head Stock

- Saddle

- Bed or Pillar Type

- Clamping Vice

- Die Head.

Listed below are the ranges in which our Scaffolding Pipe Thread Cutting Machines manufactured by industrial machinery corporation can act in:

- 1/4" to 1" do/-

- 3/8" to 1.12" do/-

- 1/2" to 2.1/2" do/-

Specifications:

| Model | 1/2" to 2.1/2" (12MM to 65MM) (Bed Type) | 1/2" to 2.1/2" (12MM to 65MM) (Pillar type) |

| Saddle Movement | 24" | 16" |

| Spindle Speed Range | 45-90 | 60-90-120 |

| Number of Spindle Speed | 2 | 3 |

| Threading Capacity | 1/2" to 2.1/2" | 1/2" to 2.1/2" |

| Production per Hour | 25-40 | 35-60 |

| H.P. Required | 7.5 H.P. | 7.5 H.P. |

| Lead Screw | Optional | Optional |

| Weight (KG) Approx. | 990 | 1100 |

Scaffolding Pipe Thread Cutting Machine Tangential Chaser

IMC Tangential Chasers are manufactured from imported High-Speed Steel which must pass exacting metallurgical standard. Experienced heat treatment with the automatically imported heat treatment plant and imported Testing equipment, assure that they will perform satisfactorily in service and produce quality threads within the tolerance for which they ware intended. These Tangential Chasers are used in Scaffolding Pipe Thread Cutting Machine.

IMC Chaser is interchangeable. If one Pc. Of a chaser, the set is damaged & is beyond use. Then same No. pc. Of the other chaser set lying in stock may be used and there will not be any difference in threading performance and the damaged set can be replaced without the necessity of replacing the entire set.

Read More...