Surface Grinder Machine

Industrial Machinery Corporation has become one of the most popular names in the field of industrial machine manufacturing. With over seven years of experience, we have become proficient in providing ...

VIEW MOREIndustrial Machinery Corporation has uniquely positioned ourselves as a dependable firm, engaged in manufacturing and supplying a commendable array of Resharpening Machine. These Tools and Taps Resharpening Machines are manufactured using excellent quality raw material and latest technology by our skilled professionals. In order to ensure quality, this Tap and Tool Grinder Machine are stringently tested on various parameters by our experts. Apart from this, remarkable quality and durability increase the demand of our offered range in the market. No injure during the re-sharpening process and saving time from re-sharpening taps and tools.

VIEW SPECIFICATIONS

Industrial Machinery Corporation has uniquely positioned itself as a dependable firm, engaged in manufacturing and supplying a commendable array of Resharpening machines. These Tools and Taps Resharpening Machines are manufactured using excellent quality raw materials and the latest technology by our skilled professionals. In order to ensure quality, this Tap and Tool Grinder Machine is stringently tested on various parameters by our experts. Apart from this, remarkable quality and durability increase the demand for our offered range in the market. No injuries during the re-sharpening process and saving time from re-sharpening taps and tools.

The Tap and Tool Grinder Machine is used for re-sharpen the taps and tools. Taps, like all other cutting tools, become dull through use. Dull taps can produce either oversize or undersized holes. They may chip, produce poor threads, or break in extreme cases. This Tap and Tool Grinder Machine is used for dull or bad tools re-sharpening outside and saving the cost of hiring a skilled worker for re-sharpening taps and tools. This Tap and Tool Grinder Machine will be saving you cost and time.

Smaller sizes of taps are generally reconditioned by grinding the chamfer portion only, while larger taps may also require flute grinding. Taper pipe taps must be sharpened by grinding the flutes and spiral-pointed taps must be reground in the angular portion of the flute as well as on the chamfer.

Flute grinding or spiral point grinding should also be done on a tap reconditioning machine or on a cutter grinder. Flute grinding wheels should be shaped with a diamond dresser of the appropriate type to produce a rake face or hook face as required. Both chamfers and flutes should be ground carefully so as not to burn the cutting edges of the tap, careful grinding will also produce a smooth finish on the tap. Wheels of K or L hardness and 60-grain or finer should be used.

Industrial Machinery Corporation has become one of the most popular names in the field of industrial machine manufacturing. With over seven years of experience, we have become proficient in providing ...

VIEW MORE

We are a noteworthy manufacturer and provider of premium quality Buffing Machine that is accessible with us in various details. This machine has propelled support for polishing the materials, machine, ...

VIEW MORE

We, "Industrial Machinery Corporation" established in 2011, have been recognized as a coveted supplier of a wide assortment of Threading Machine, Bar Threading Machine, Bolt Threading Machine, Rod Thr ...

VIEW MORE

Industrial Machinery Corporation is a professional Pipe Cutting Machine manufacturer based in India. Pipe Cutting Machines are manufactured using the best quality raw material, components, and cutting ...

VIEW MORE

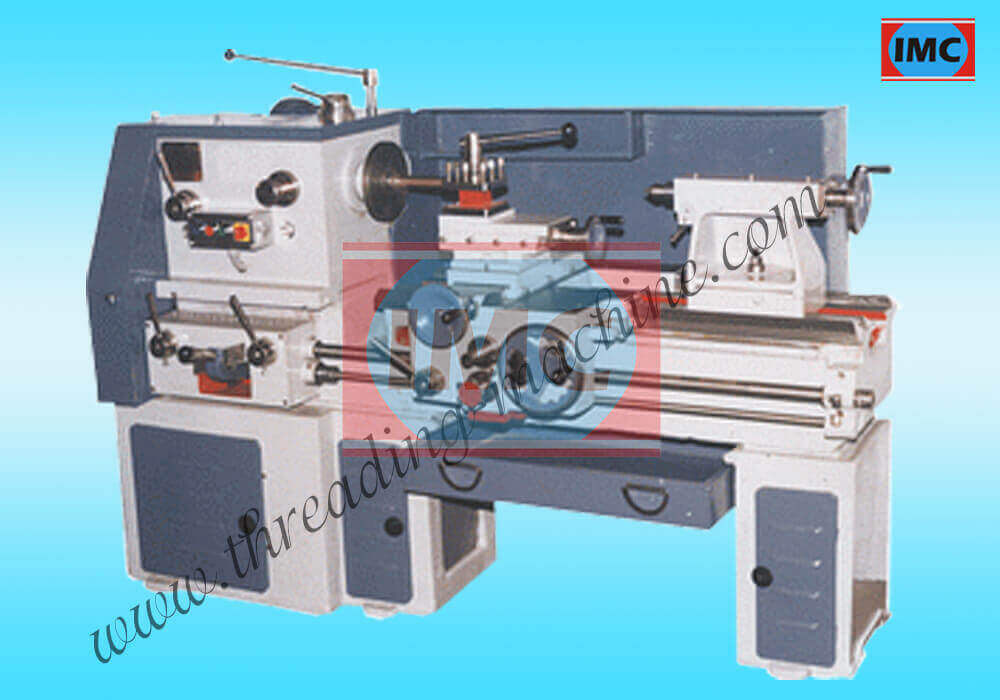

For seven years, industrial machinery corporation has been the largest Lathe Machines manufacturer in India. We have been engaged in manufacturing and supplying of lathe machines since 2011 when our c ...

VIEW MORE

The quality of machines that we have been making since our establishment ten years back has been matchless and unparalleled. It is due to this habit of supplying all our clients with best quality indu ...

VIEW MORE