Mig Welding Machine

Being in the business of welding machine producing for over 7 years, what we would advise all of the purchasers with respect to MIG Welding Machine is to have a point by point discussion on what are t ...

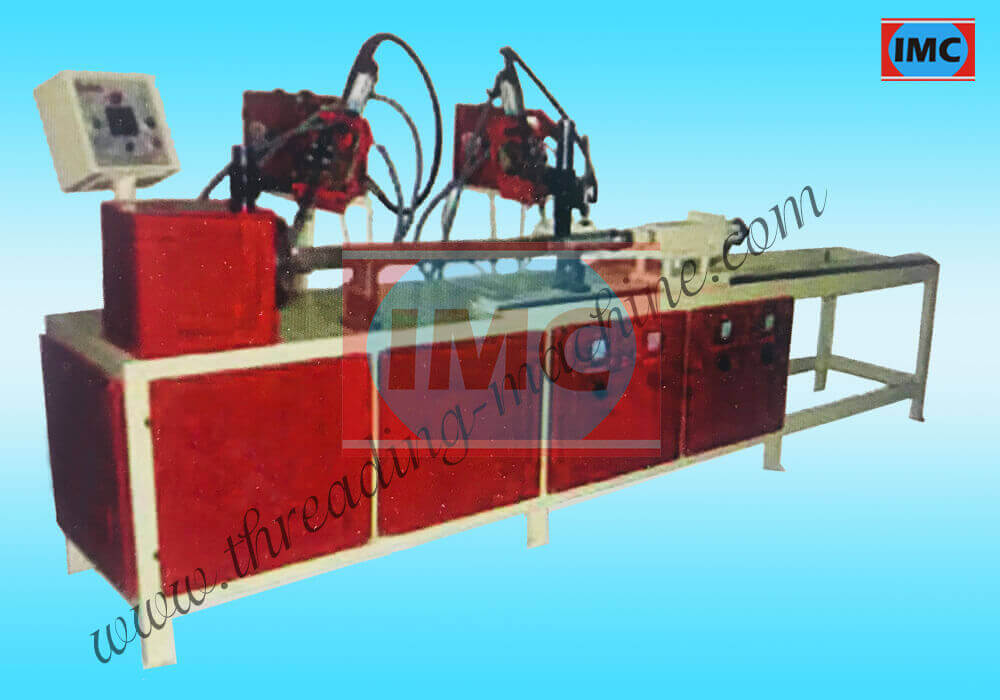

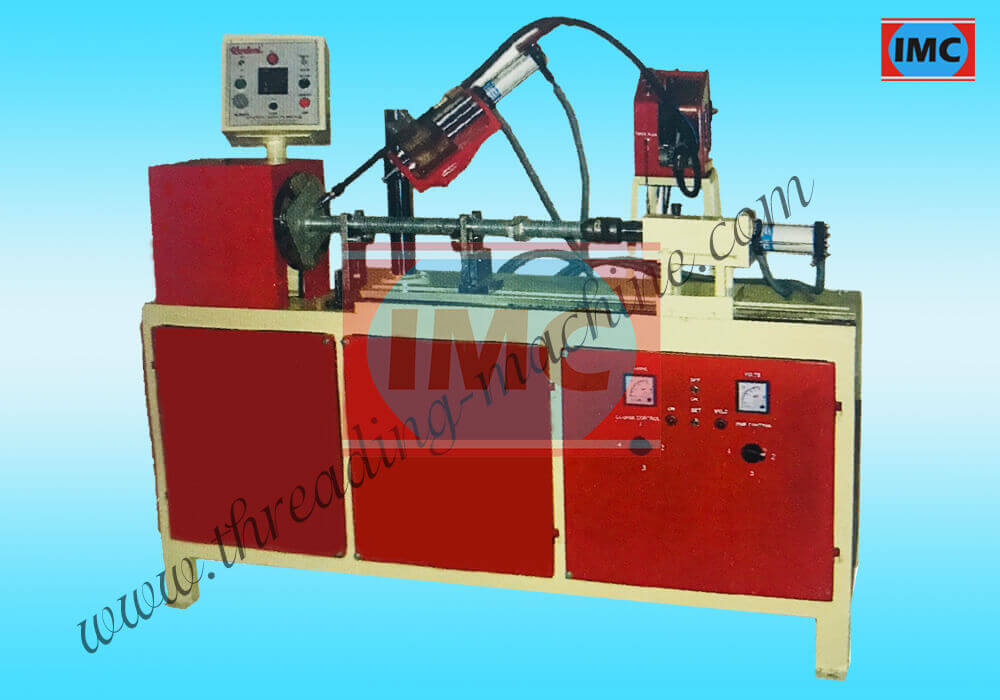

VIEW MOREAutomatic Inner prop welding machine is used to weld base plate with a pipe without making any joint between them, It gives high production and accuracy to the product. Inner prop is used with a combination of Outer prop welding to make a structure. All the components are used in combination with each other Base jack welding machines, Outer prop welding machines, Cuplock welding machines, Ringlock welding machines.

VIEW SPECIFICATIONSIn the realm of modern construction, efficiency, and precision play vital roles in delivering projects of exceptional quality within strict timelines. Industrial Machinery Corporation (IMC) has once again raised the bar by introducing its groundbreaking innovation, the IMC Inner Prop Welding Machine. This cutting-edge equipment is set to revolutionize the construction industry, offering unmatched efficiency, reliability, and cost-effectiveness in inner prop welding applications.

Enhancing Construction Efficiency:

The IMC Inner Prop Welding Machine is meticulously engineered to streamline the inner prop welding process, a critical step in construction projects requiring temporary support systems. By eliminating manual welding methods, IMC has paved the way for significant time and cost savings. This innovative machine automates and optimizes the inner prop welding process, ensuring seamless and precise welds with consistent quality.

Unparalleled Precision and Quality:

With a focus on precision and quality, the IMC Inner Prop Welding Machine employs advanced welding technologies and intelligent control systems. The machine utilizes state-of-the-art sensors and actuators to ensure precise alignment, controlled heat distribution, and optimal weld penetration. This results in robust and durable welds, surpassing industry standards and guaranteeing the structural integrity of the inner props.

Effortless Operation and User-Friendly Interface:

IMC understands the importance of user-friendly equipment, and the Inner Prop Welding Machine reflects that commitment. Designed for seamless operation, the machine features an intuitive interface that simplifies setup and operation. The automated functions reduce the reliance on highly skilled welders, making it accessible to a wider range of operators without compromising on the quality of the welds. Additionally, the machine's versatility allows for adjustable parameters to accommodate various inner prop sizes, ensuring adaptability to diverse construction needs.

Unrivaled Safety and Reliability:

IMC prioritizes safety in every aspect of their machinery, and the Inner Prop Welding Machine is no exception. Equipped with advanced safety features, such as automatic shutdown mechanisms, temperature monitoring, and real-time fault detection, it provides a secure working environment for operators. The machine undergoes rigorous testing and adheres to international safety standards, assuring its reliability and minimizing the risk of accidents.

Environmental Responsibility:

IMC recognizes the importance of sustainable practices in the construction industry. The Inner Prop Welding Machine incorporates energy-efficient technologies, minimizing power consumption without compromising on performance. By reducing energy usage and emissions, IMC contributes to environmental preservation and sustainable development.

The IMC Inner Prop Welding Machine represents a significant leap forward in construction efficiency and productivity. With its unrivaled precision, user-friendly interface, and commitment to safety, this innovative equipment sets new industry benchmarks. By investing in IMC's Inner Prop Welding Machine, construction companies can harness the power of automation and achieve unparalleled quality, reduced costs, and accelerated project completion. IMC's unwavering dedication to manufacturing excellence continues to shape the future of the construction industry, where efficiency and innovation converge for exceptional results.

| Electric Supply | Single Phase 220 Volt HZ 50/60 | ||

| Speed | 2 to 10 RPM | ||

| Motor Drive | AC Inverter Type | ||

| Motor | Type AC 220-Volts-3-Phase | ||

| Torch Clamping | PNEUMATIC | ||

| Length Adjustment | 150 to 2400 mm | ||

| Dimension | L x W x H 11.3x2.5x5.3 (Foot) |

Being in the business of welding machine producing for over 7 years, what we would advise all of the purchasers with respect to MIG Welding Machine is to have a point by point discussion on what are t ...

VIEW MORE

Founded in the year 2011 at Ludhiana, Punjab, India. we “Industrial Machinery Corporation” are manufacturing and exporting a qualitative of Welding Machines, Scaffolding Welding Fixtures, Welding ...

VIEW MORE

Founded in the year 2011 at Ludhiana, Punjab, India, we “Industrial Machinery Corporation” are manufacturing and exporting a qualitative of Welding Machines, Scaffolding Welding Fixtures, Welding ...

VIEW MORE

Industrial Machinery Corporation got incorporated in the year 2011 in Ludhiana, Punjab, India. A decade-long business journey has helped us to earn a reputable position in the market and we are a lead ...

VIEW MORE

Industrial Machinery Corporation has gained a huge name as an expert in manufacturing Cups and lock pins Tagging Machines and this is true too, as we truly have the best team and set-up to manufacture ...

VIEW MORE

The name of Industrial Machinery Corporation is ranked in top ten manufacturers and exporters of welding machines owing to its best quality welding machinery that we have manufactured which are popula ...

VIEW MORE

Are you in need of a cutting-edge solution for punching holes in scaffolding pipes? Look no further than IMC, a trusted manufacturer and exporter of construction machinery. Our Scaffolding Pipe Punchi ...

VIEW MORE

Are you seeking a reliable and high-performance welding solution for scaffolding prop nut cup handles?Look no further than IMC, a leading manufacturer and exporter of construction machinery. Our Scaf ...

VIEW MORE

Are you searching for an advanced welding solution for double-sided scaffolding prop production?Look no further than IMC, a renowned manufacturer and exporter of construction machinery. Our Double-Si ...

VIEW MORE

Are you in search of an advanced and automated solution for producing scaffolding cup sleeve nuts, handles, and G pins? Look no further than IMC, a leading manufacturer and exporter of construction ma ...

VIEW MORE