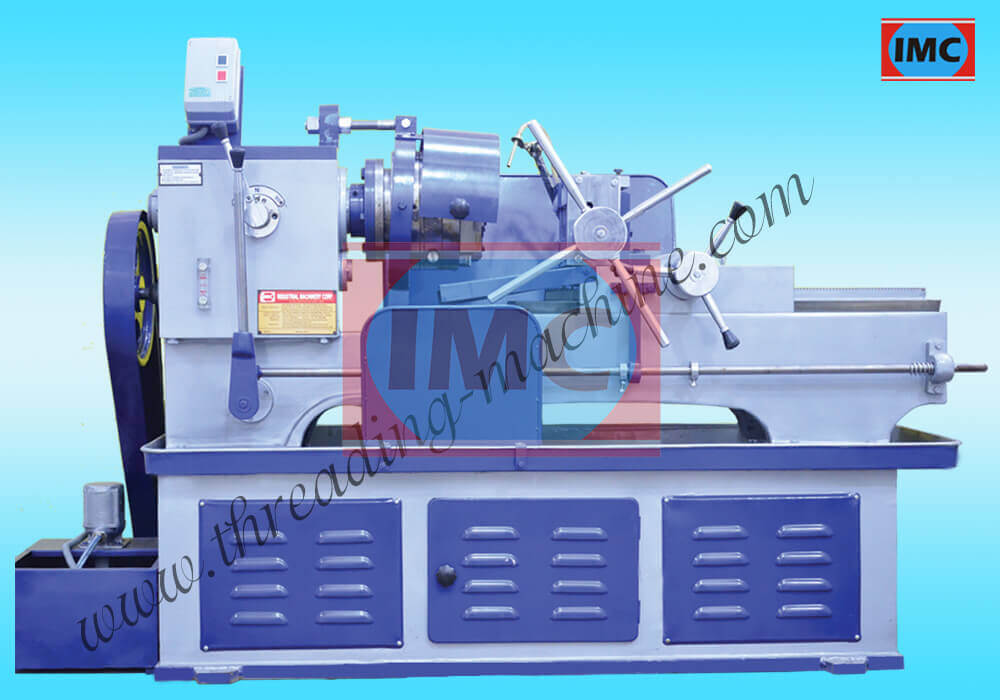

Pipe Threading Machine

Industrial Machinery Corporation has become a very familiar name in the world of industrial machine manufacturers owing to its continuous hard work and supplying best quality industrial machines to ou ...

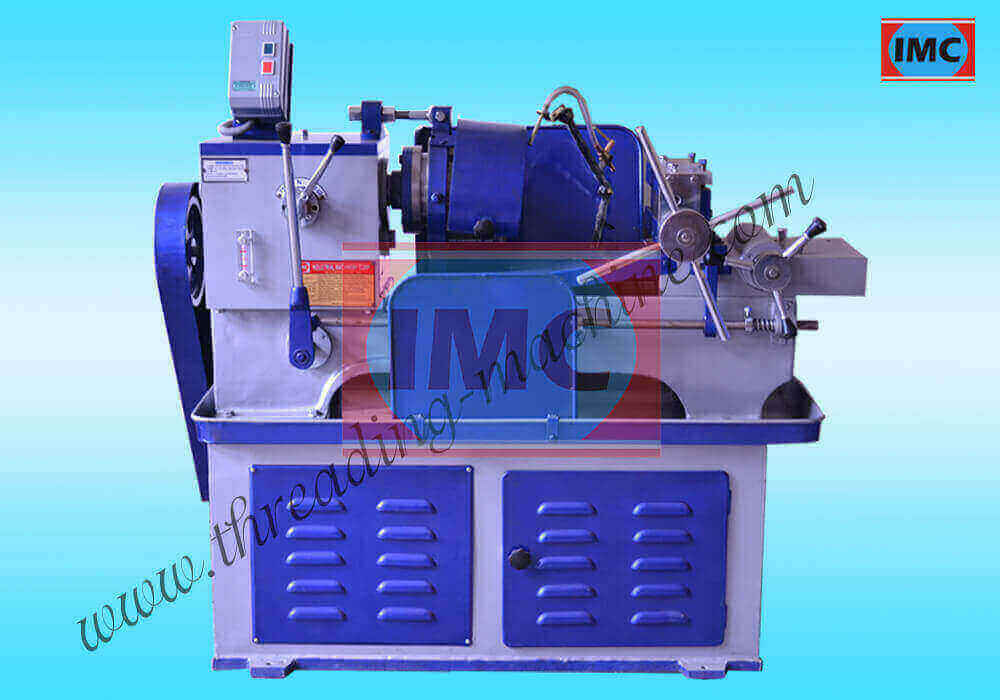

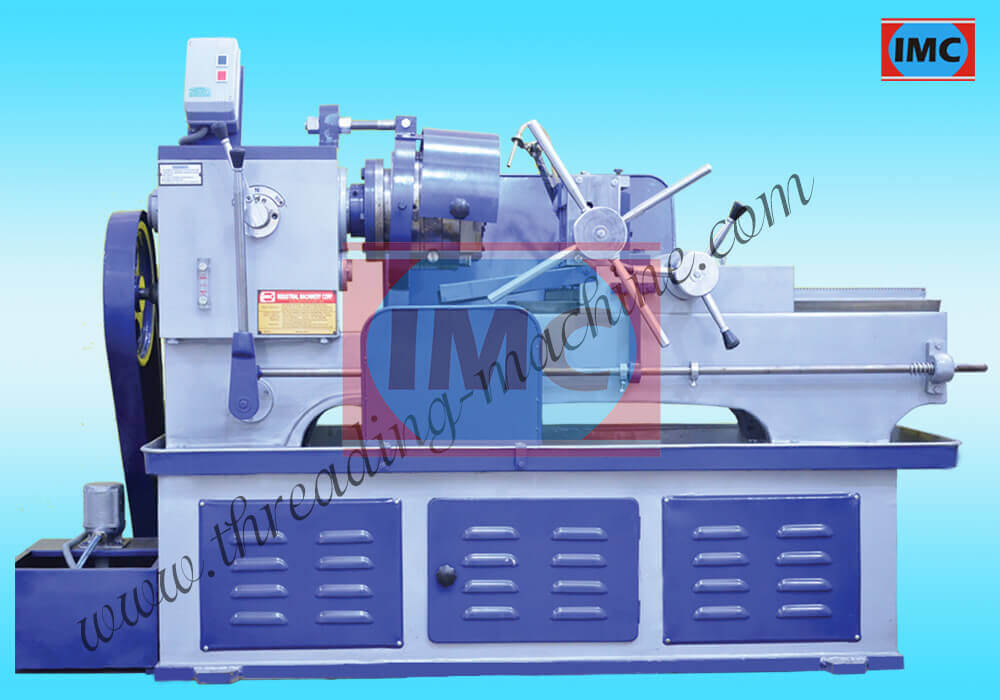

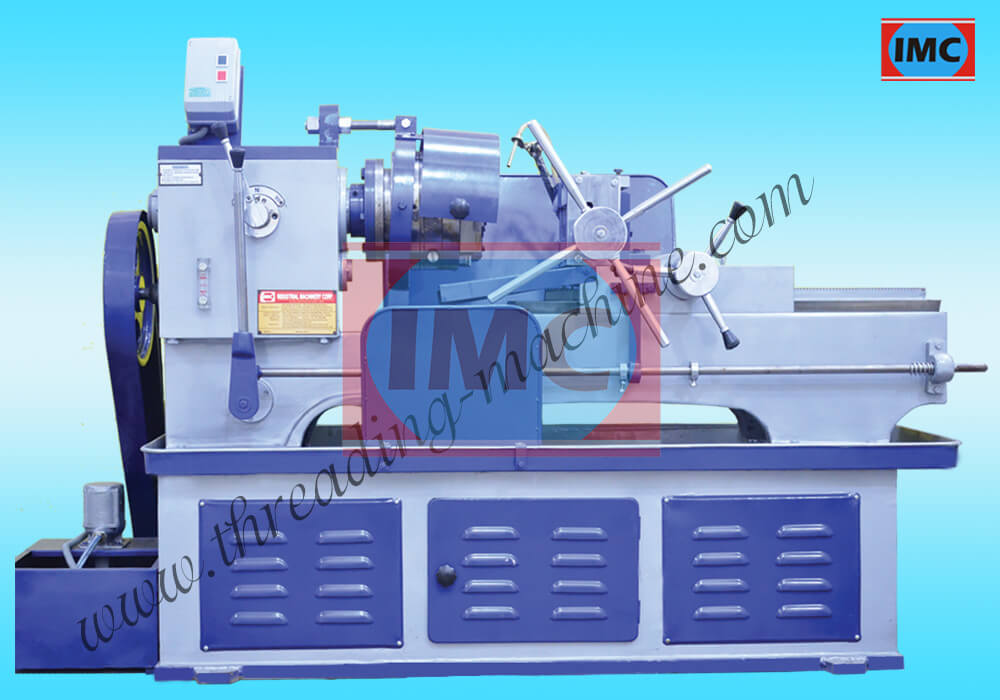

VIEW MOREElectric Conduit Pipe Threading Machine is used to thread the external area of the conduit pipes. IMC Machines highly specialized and can be used solely for industry-specific purposes. There are only a few companies in the world that fabricate this particular type of machine.

VIEW SPECIFICATIONSElectric Conduit Pipe Threading Machine is used to thread the external area of the conduit pipes. IMC Machines were highly specialized and can be used solely for industry-specific purposes. There are only a few companies in the world that fabricate this particular type of machine.

One company that has won much acclaim in the area of conduit pipe threading machines. We have a large range of threading machines. The company has immense experience in the field of such machines. Also, the same to ensure that the customers get value for the money that they are spending.

The material used for fabrication is of high grade. There is an absolute assurance that there will be no issues during usage.

If one chooses to purchase conduit pipe threading machines from a company that is reputed as the Industrial Machinery Corporation. The demand for these machines has grown manifold in the past few years. A quality product always stands out in the market, and will always be able to create a niche for itself. This is exactly why these machines, unlike several others, have been able to satiate the requirements of numerous big organizations, by providing them efficient and relatively maintenance-free service.

An electric conduit pipe thread cutting machine is a piece of equipment used in the plumbing, electrical, and construction industries to cut threads onto conduit pipes. Conduit pipes are used to protect and route electrical wiring in buildings, and threaded ends allow for easy connection and installation.

Here's a general description of how an electric conduit pipe thread cutting machine typically works:

Electric Power: These machines are powered by electricity, typically from a standard electrical outlet. This power drives the cutting mechanism.

Thread Cutting Mechanism: The machine consists of a cutting head or die head that holds the cutting dies. These dies are made of hardened steel and are designed to cut precise threads onto the ends of conduit pipes.

Pipe Holding Mechanism: The conduit pipe is securely held in place by a clamp or vise mechanism to ensure stability during the cutting process.

Adjustability: Many machines offer adjustable settings to accommodate different pipe diameters and thread sizes. This allows for versatility in the types of pipes that can be threaded.

Control Panel: There might be a control panel or

interface where the user can adjust settings such as the thread pitch or depth of the cut.

Safety Features: Electric conduit pipe thread cutting machines often come with safety features such as emergency stop buttons, protective guards around the cutting area, and safety switches to prevent accidental operation.

Ease of Use: These machines are designed to be user-friendly, with straightforward controls and intuitive operation, allowing even novice users to cut accurate threads with minimal effort.

Durability: Given the industrial nature of their use, these machines are typically built to be durable and withstand frequent use in rugged environments.

Overall, an electric conduit pipe thread cutting machine is an essential tool for professionals in the plumbing, electrical, and construction industries, providing a fast, efficient, and precise method for threading conduit pipes for various applications.

| MODEL | 1/4" TO 1" (6MM to 25MM) (BED TYPE) | 3/8" TO 1.1/2" (10MM to 40MM) (BED TYPE) | 1/2" TO 2.1/2" (12MM to 65MM) (BED TYPE) |

| Saddle Movement | 10" | 13" | 22" |

| Spindle Speed Range | 75-140 | 75 -140 | 45 - 90 |

| Number of Spindle Speed | 2 | 2 | 2 |

| Threading Capacity | 1/4" to 1" | 3/8" to 1.1/2" | 1/2" to 2.1/2" |

| Production per Hour | 60-80 | 60-80 | 70-90 |

| H.P. Required | 3 H.P. | 3 H.P. | 7.5 H.P. |

| Lead Screw | Optional | Optional | Optional |

| Weight (KG) Approx. | 500 | 550 | 990 |

Industrial Machinery Corporation has become a very familiar name in the world of industrial machine manufacturers owing to its continuous hard work and supplying best quality industrial machines to ou ...

VIEW MORE

For many years Bar Thread Cutting Machine has been the best and most used machine for all bar thread cutting and related purposes. Bar Thread Cutting Machine has lived up to the reputation of being th ...

VIEW MORE

In a very short span of time, Industrial Machinery Corporation has been named among the best bolt threading machine manufacturers and suppliers from India. The main reason behind that is our continuou ...

VIEW MORE

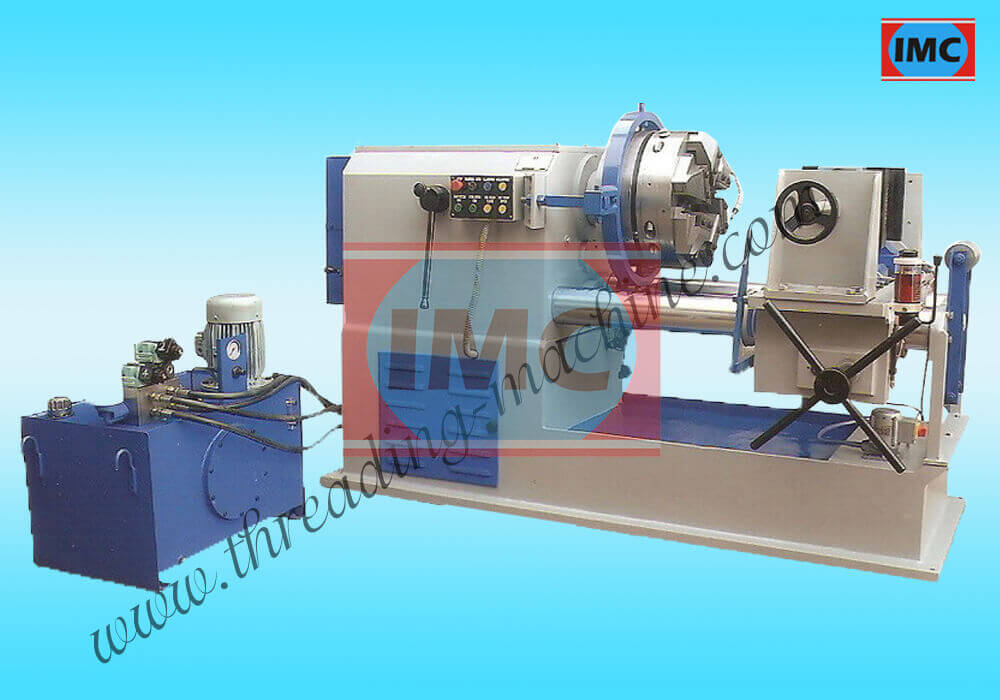

Industrial Machinery Corporation has been in this business of manufacturing and supplying Hydraulic Pipe Threading Machine for more than a decade now. For all these seven years, we have been researchi ...

VIEW MORE

Rod Threading Machine is a machine that we take pleasure in describing. It is perhaps the best crafted and artistically designed at industrial machinery corporation factory at Ludhiana. We have been i ...

VIEW MORE

We have the wide range of semi-automatic Steel TMT Chaser Rebar Threading Machine which is used for the site projects and it does outside threading on TMT bars. Steel TMT Chaser Rebar Threading Machin ...

VIEW MORE