Pipe Threading Machine

Industrial Machinery Corporation has become a very familiar name in the world of industrial machine manufacturers owing to its continuous hard work and supplying best quality industrial machines to ou ...

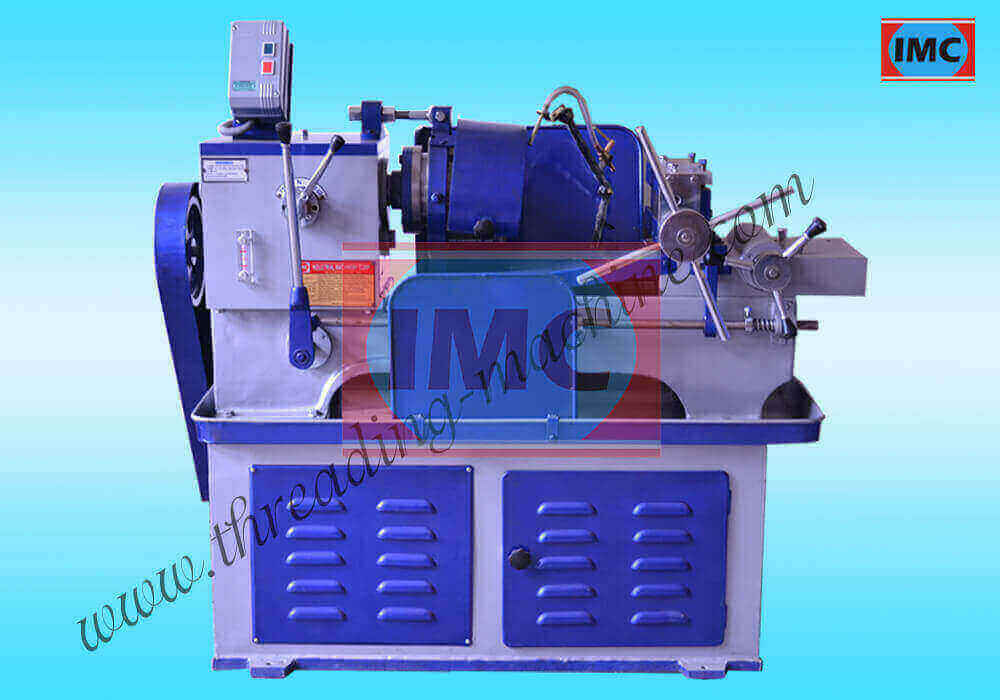

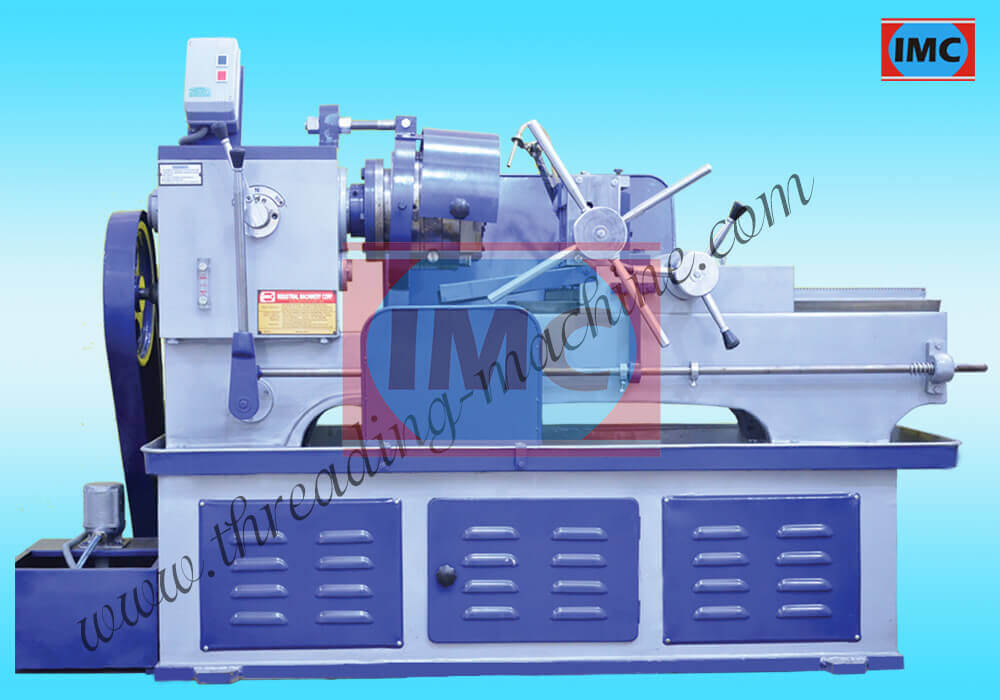

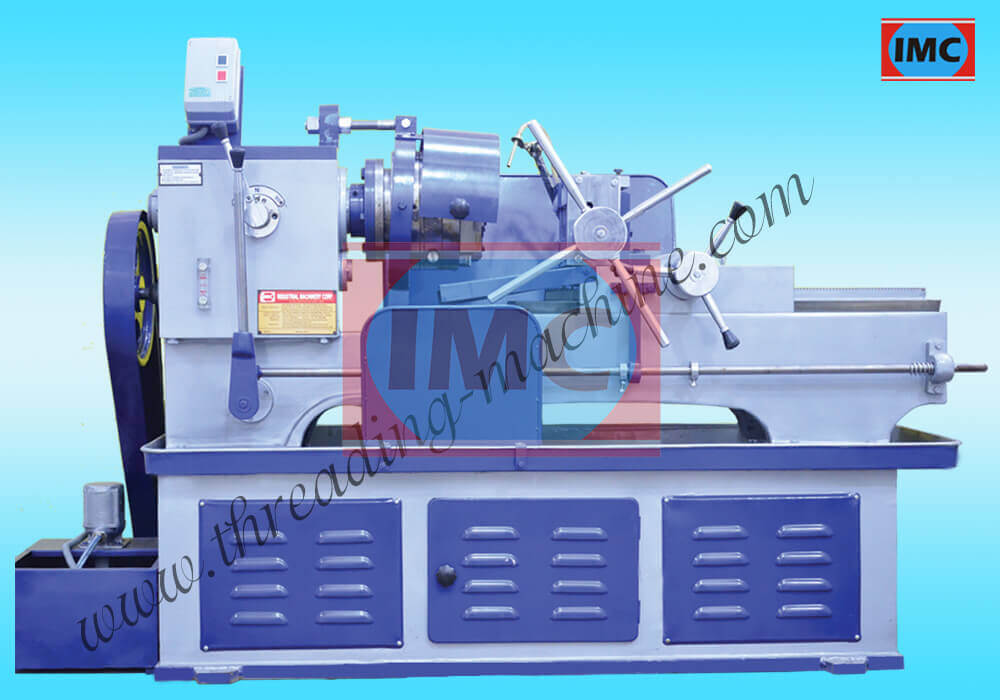

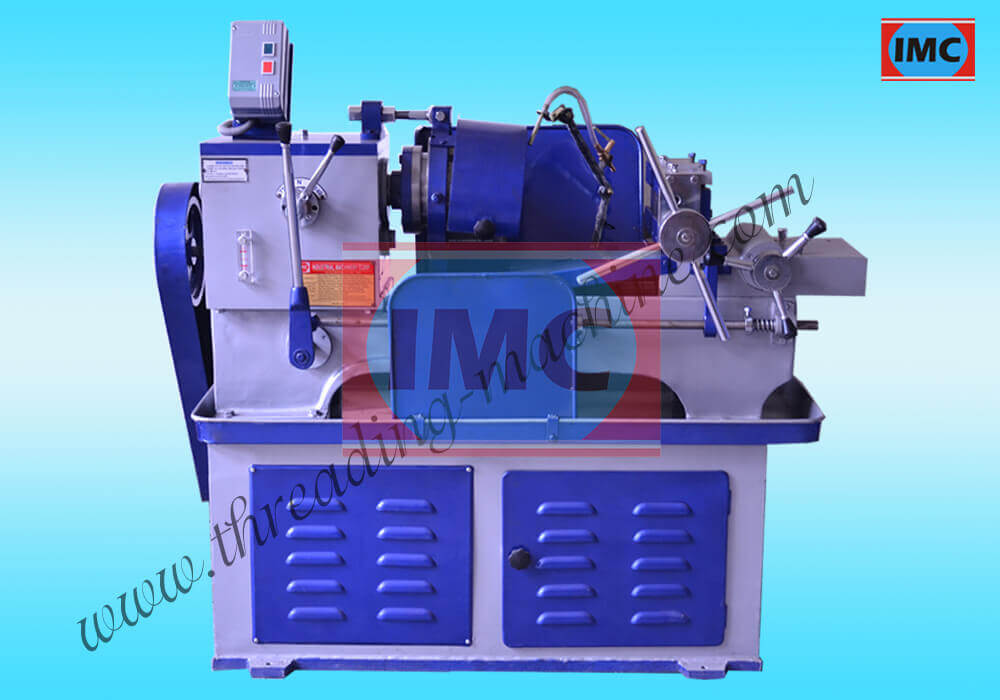

VIEW MORERod Threading Machine is a machine that we take pleasure in describing. It is perhaps the best crafted and artistically designed at industrial machinery corporation factory at Ludhiana. We have been in this business for ten years and have all the needed experience for manufacturing our Rod Threading Machine. The popularity of our Rod Threading Machine has made us best manufacturers of rod threading machine in India. Our Rod Threading Machine has become the most admired machine in the segment today and main reason behind this is that we use only the best quality raw material to build our machines. The raw material used at our factory is strictly checked for quality by our quality assessment team prior to getting used. This team has been given full rights to reject the raw material with any flaw of even a tinge of defect. It is due to the use of best quality raw material that our Rod Threading Machine is built very strong and sturdy which is ready to face all the wear and tear that may occur in a factory. In many of the tests, our Rod Threading Machine has proved its strength and strong body by working on the fullest speed for as long as 18-19 hours continuously. We get all our machines designed by international designers, and that is why our Rod Threading Machine is versatile and easiest to operate. Due to its design and make, this Rod Threading Machine has been producing the most precise and accurate threading outcome. This machine has the capability to work for long hours, owing to its powerful motor and the specially made and fitted gear box. The gear box that we have fitted in this Rod Threading Machine is a bit heavier than ordinary gearboxes and gives full support to the spindle while the machine is working in its maximum speed. Apart from this, there are many other features in our Rod Threading Machine which makes it better than rod threading machines from other manufacturers as well as the bestseller.

VIEW SPECIFICATIONSRod Threading Machine is a machine that we take pleasure in describing. It is perhaps the best crafted and artistically designed at industrial machinery corporation factory at Ludhiana. We have been in this business for ten years and have all the needed experience for manufacturing our Rod Threading Machine. The popularity of our Rod Threading Machine has made us best manufacturers of rod threading machine in India. Our Rod Threading Machine has become the most admired machine in the segment today and main reason behind this is that we use only the best quality raw material to build our machines. The raw material used at our factory is strictly checked for quality by our quality assessment team prior to getting used. This team has been given full rights to reject the raw material with any flaw of even a tinge of defect. It is due to the use of best quality raw material that our Rod Threading Machine is built very strong and sturdy which is ready to face all the wear and tear that may occur in a factory. In many of the tests, our Rod Threading Machine has proved its strength and strong body by working on the fullest speed for as long as 18-19 hours continuously. We get all our machines designed by international designers, and that is why our Rod Threading Machine is versatile and easiest to operate. Due to its design and make, this Rod Threading Machine has been producing the most precise and accurate threading outcome. This machine can work for long hours, owing to its powerful motor and the specially made and fitted gear box. The gear box that we have fitted in this Rod Threading Machine is a bit heavier than ordinary gearboxes and gives full support to the spindle while the machine is working in its maximum speed. Apart from this, there are many other features in our Rod Threading Machine which makes it better than rod threading machines from other manufacturers as well as the bestseller.

A Rod Threading Machine is used in factories basically for cutting external threads on the rods and chasing principle is used by it in which the machine makes the rod to stay unmovable at one place and allowing the die head to rotate around and create threads on a rod. Using chasing method and HSS tangential chasers, this machine can create a big variety of external threads on a rod but will totally perform as per the cutter installed that time.

Names of some threads that a Rod Thread Cutting Machine can cut are:-| MODEL | 1/4" TO 1" (6MM to 25MM) (BED TYPE) | 3/8" TO 1.1/2" (10MM to 40MM) (BED TYPE) | 1/2" TO 2.1/2" (12MM to 65MM) (BED TYPE) |

| Saddle Movement | 10" | 13" | 22" |

| Spindle Speed Range | 75-140 | 75 -140 | 45 - 90 |

| Number of Spindle Speed | 2 | 2 | 2 |

| Threading Capacity | 1/4" to 1" | 3/8" to 1.1/2" | 1/2" to 2.1/2" |

| Production per Hour | 60-80 | 60-80 | 70-90 |

| H.P. Required | 3 H.P. | 3 H.P. | 7.5 H.P. |

| Lead Screw | Optional | Optional | Optional |

| Weight (KG) Approx. | 500 | 550 | 990 |

Rod Threading Machine Tangential Chaser

IMC Threading Tangential Chasers are manufactured from imported High-Speed Steel which must pass exacting metallurgical standard. Experienced heat treatment with the automatically imported heat treatment plant and imported Testing equipment, assure that they will perform satisfactorily in service and produce quality threads within the tolerance for which they ware intended. These Tangential Chasers are used in Rod Threading Machine.

IMC Threading Chaser is interchangeable. If one Pc. Of a chaser, the set is damaged & is beyond use. Then same No. pc. On the other chaser set lying in stock may be used and there will not be any difference in threading performance and the damaged set can be replaced without the necessity of replacing the entire set.

Read More..

Industrial Machinery Corporation has become a very familiar name in the world of industrial machine manufacturers owing to its continuous hard work and supplying best quality industrial machines to ou ...

VIEW MORE

For many years Bar Thread Cutting Machine has been the best and most used machine for all bar thread cutting and related purposes. Bar Thread Cutting Machine has lived up to the reputation of being th ...

VIEW MORE

In a very short span of time, Industrial Machinery Corporation has been named among the best bolt threading machine manufacturers and suppliers from India. The main reason behind that is our continuou ...

VIEW MORE

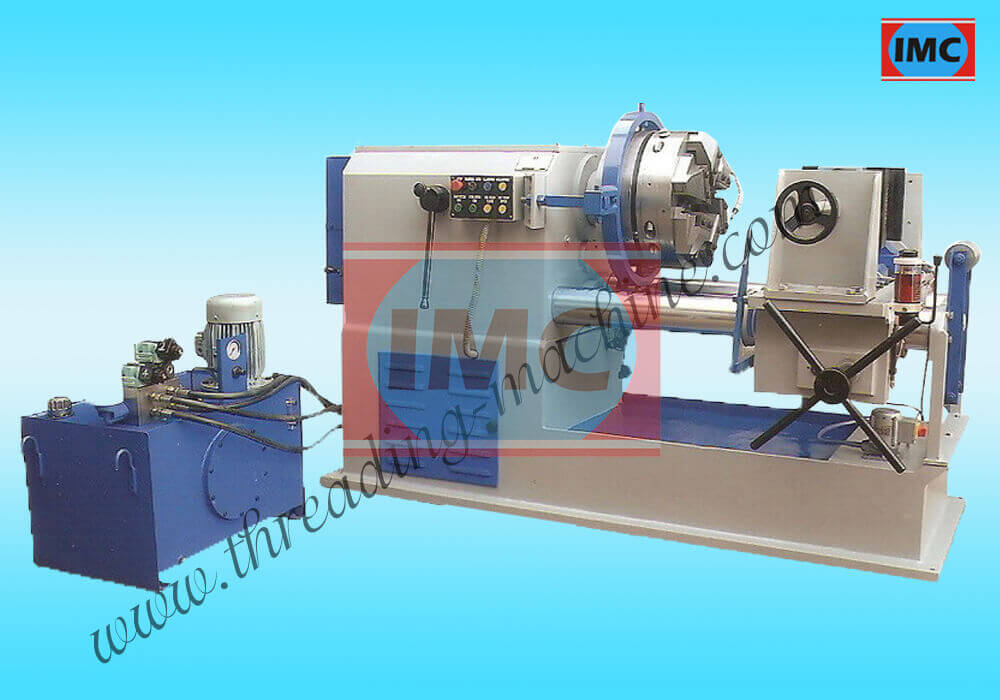

Industrial Machinery Corporation has been in this business of manufacturing and supplying Hydraulic Pipe Threading Machine for more than a decade now. For all these seven years, we have been researchi ...

VIEW MORE

We have the wide range of semi-automatic Steel TMT Chaser Rebar Threading Machine which is used for the site projects and it does outside threading on TMT bars. Steel TMT Chaser Rebar Threading Machin ...

VIEW MORE

Electric Conduit Pipe Threading Machine is used to thread the external area of the conduit pipes. IMC Machines highly specialized and can be used solely for industry-specific purposes. There are only ...

VIEW MORE