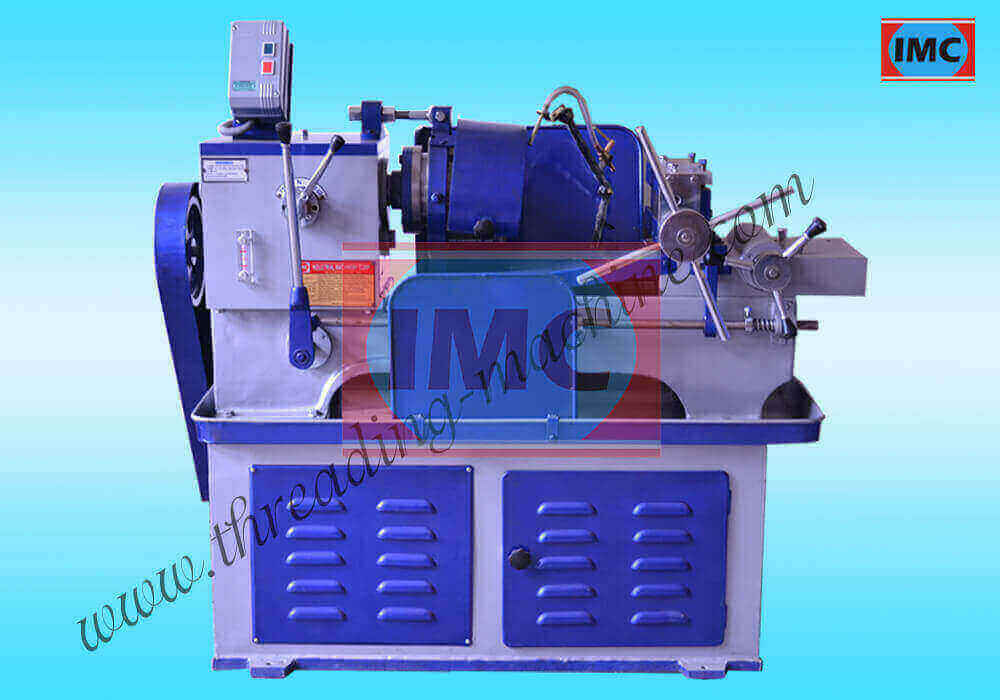

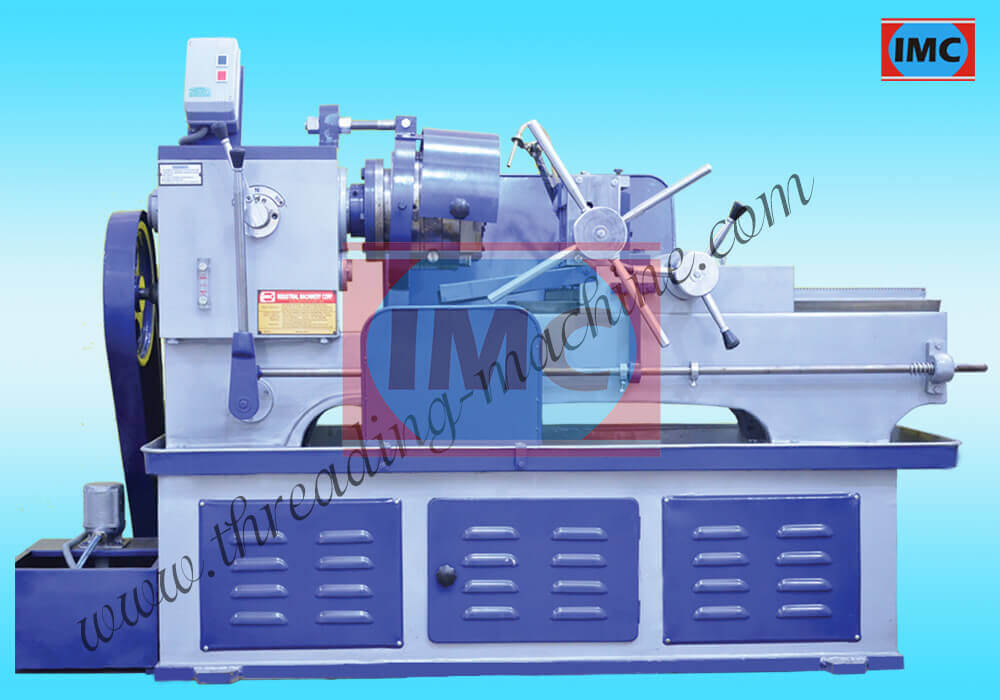

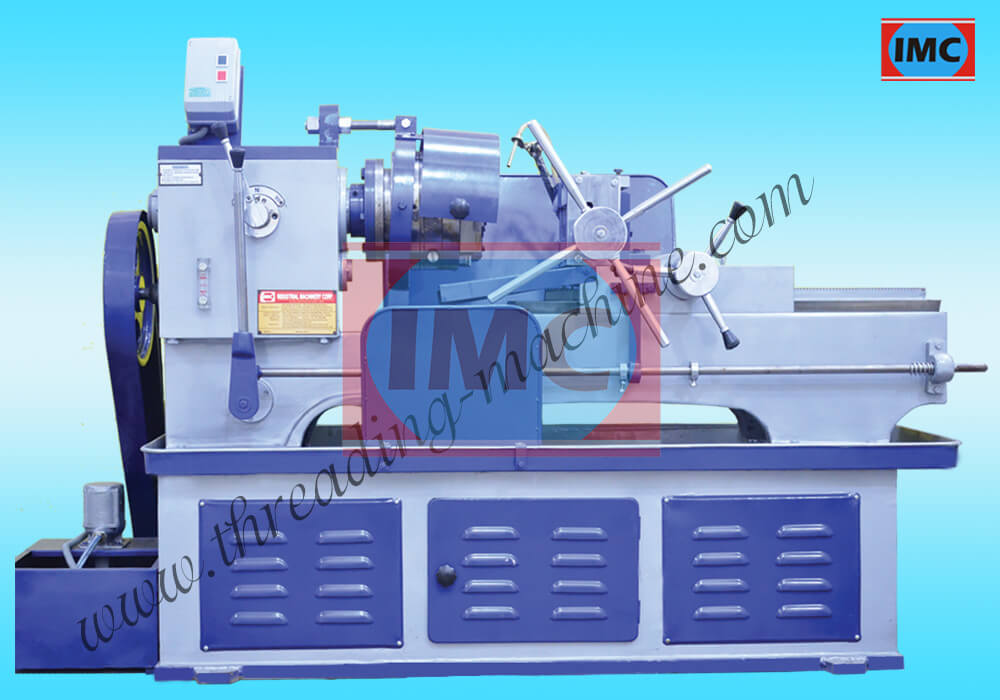

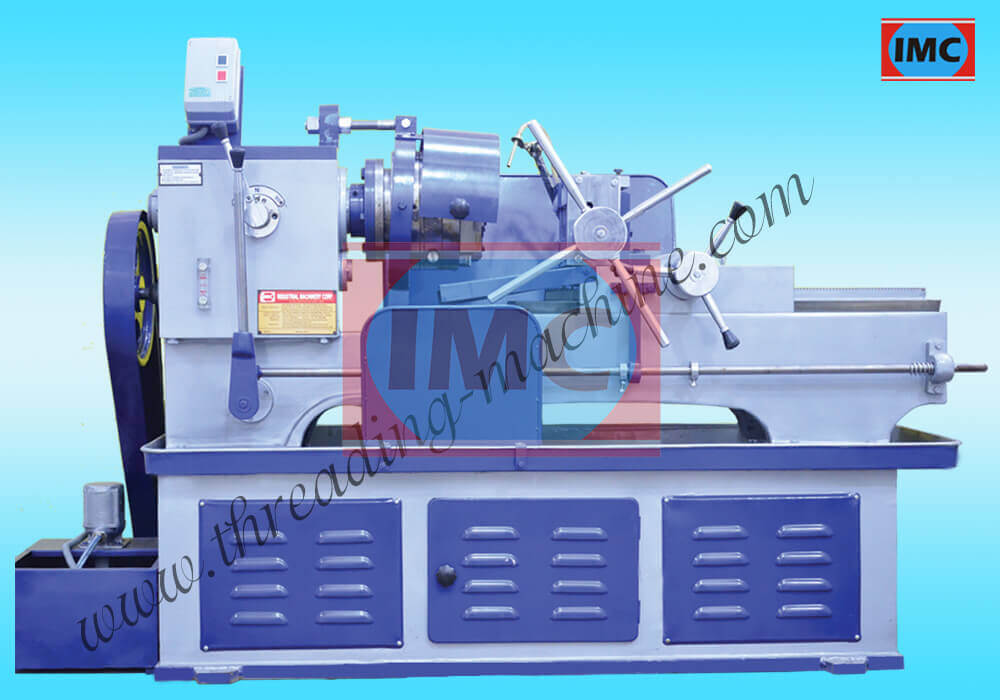

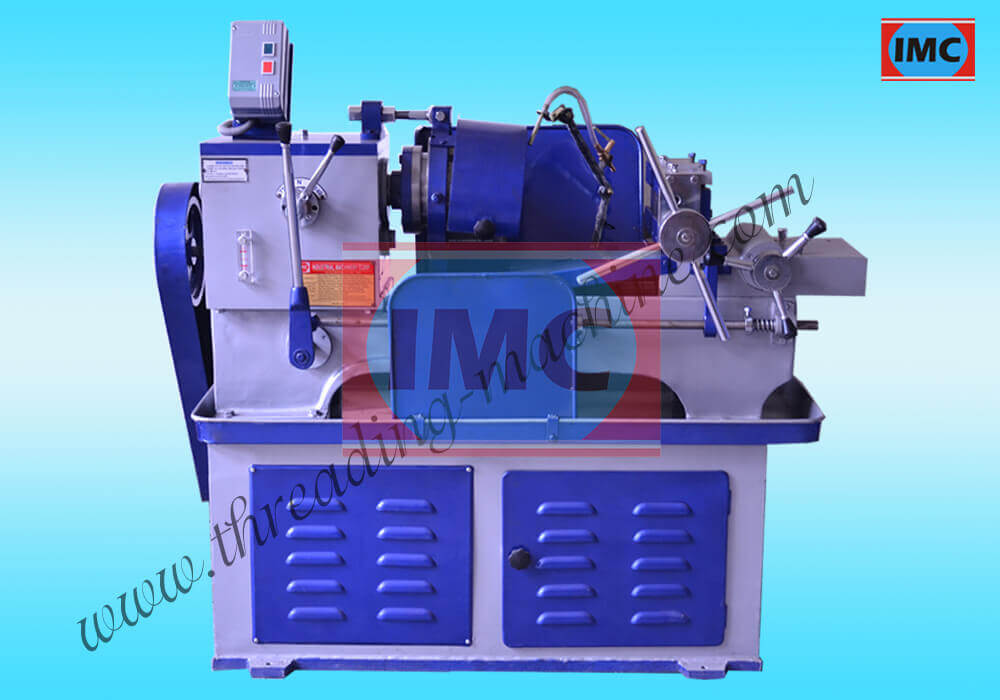

Pipe Threading Machine

Industrial Machinery Corporation has become a very familiar name in the world of industrial machine manufacturers owing to its continuous hard work and supplying best quality industrial machines to ou ...

VIEW MOREIndustrial Machinery Corporation has been in this business of manufacturing and supplying Hydraulic Pipe Threading Machine for more than a decade now. For all these seven years, we have been researching and developing all our products and launching upgraded versions every now and then. Now we have come up with an updated Hydraulic Pipe Threading Machine and we have designed it to perform many operations for a long period of time without any fault or blemish in the quality of the results. This machine is unique and distinct from Hydraulic Pipe Threading Machines from other manufacturers in many ways as due to its strong engine, it is capable of working for long hours in the toughest working conditions. Our Machines have gained this recognition for many other reasons which include efficiency, strength, robustness, sleek and light-weighted design, handiness, easy-to-operate, and user-friendliness. It is due to these aforementioned that our machines is the most demanded by the buyers and surpasses the demands of all other machine manufacturers and exporters in India. The Hydraulic Pipe Threading Machine that we make here uses only the finest quality steel raw material and during the manufacturing process, every alertness is kept just to be sure that the quality of this machine is maintained without the slightest tempering. It is due to our tradition of using the finest quality raw material and maintaining all the standards while manufacturing that this machine’s design looks so sleek and feminine but has tremendous power when in operation. Using this incredible force, this Machines can draw the following threads on a pipe:

VIEW SPECIFICATIONSIndustrial Machinery Corporation has been in the business of manufacturing and supplying Hydraulic Pipe Threading Machine for more than a decade now. For all these seven years, we have been researching and developing all our products and launching upgraded versions now and then. Now we have come up with an updated Hydraulic Pipe Threading Machine and we have designed it to perform many operations for a long time without any fault or blemish in the quality of the results. This machine is unique and distinct from Hydraulic Pipe Threading Machines from other manufacturers in many ways due to its strong engine, it is capable of working for long hours in the toughest working conditions. Our Machines have gained this recognition for many other reasons which include efficiency, strength, robustness, sleek and light-weighted design, handiness, easy-to-operate, and user-friendliness. It is due to these aforementioned that our machines are the most demanded by the buyers and surpass the demands of all other machine manufacturers and exporters in India. The Machines that we make here use only the finest quality steel raw material and during the manufacturing process, every alertness is kept just to be sure that the quality of this machine is maintained without the slightest tempering. It is due to our tradition of using the finest quality raw material and maintaining all the standards while manufacturing that this machine’s design looks so sleek and feminine but has tremendous power when in operation. Using this incredible force, these Machines can draw the following threads on a pipe:

The best quality that we put in our Hydraulic Pipe Threading Machines manufactured at our Ludhiana factory is that it has been fitted with a self-opening die-head and headstock gears which, when combined give added robustness and strength to the machines. These machines are also equipped with a hydraulic cylinder lead screw box nut engaging, one hydraulic pipe clamping cylinder, and one hydraulic cylinder for die-head opening with micro switches with automation with the control panel. All this equipment fitted by our Machines makes it a devil while working and allows this machine to perform non-stop for long hours without showing any signs of wear and tear or exhaustion. Keeping the flow of our decade-old tradition, we use super-fine quality steel to make all the gears of this machine too. The extra thickness on a tooth and the cut on hobbing have been given to allow the user to work under extreme noiseless conditions, even if the machine is running at its top speed. Bellows is the list of some of the main components that are added up to create the world’s best hydraulic thread cutting machines :

| Model | 1/2" to 2.1/2" (12MM to 65MM) (Pillar Type) | 1" to 4" (25MM to 100MM) (Pillar Type) | 2.1/2" to 6" (65MM to 150MM) (Pillar Type) | 4" to 8" (100MM to 200MM) (Pillar Type) |

| Saddle Movement | 12" - 16" | 10"- 12" | 8" | 8" |

| Spindle Speed Range | 60-90-120 | 40-75-115 | 25-50 | 25-50 |

| Number of Spindle Speed | 3 | 3 | 2 | 2 |

| Threading Capacity | 1/2" to 2.1/2" | 1" to 4" | 2.1/2" to 6" | 4" to 8" |

| Production per Hour | 70-90 | 35-40 | 20-25 | 15-20 |

| H.P. Power Require (960 RPM) | 7.5 H.P. | 12.5 H.P. | 15 H.P. | 20 H.P. |

| Lead Screw | Automatic | Automatic | Automatic | Automatic |

| Weight (KG) Approx. | 990 | 1600 | 1900 | 2500 |

IMC Tangential Chasers are manufactured from imported High-Speed Steel which must pass exacting metallurgical standard. Experienced heat treatment with the automatically imported heat treatment plant and imported Testing equipment, assure that they will perform satisfactorily in service and produce quality threads within the tolerance for which they ware intended. These Tangential Chasers are used for Hydraulic Pipe Threader.

IMC Chaser is interchangeable. If one Pc. Of a chaser, the set is damaged & is beyond use. Then same No. pc. Of the other chaser set lying in stock may be used and there will not be any difference in threading performance and the damaged set can be replaced without the necessity of replacing the entire set.

Read More...

Industrial Machinery Corporation has become a very familiar name in the world of industrial machine manufacturers owing to its continuous hard work and supplying best quality industrial machines to ou ...

VIEW MORE

For many years Bar Thread Cutting Machine has been the best and most used machine for all bar thread cutting and related purposes. Bar Thread Cutting Machine has lived up to the reputation of being th ...

VIEW MORE

In a very short span of time, Industrial Machinery Corporation has been named among the best bolt threading machine manufacturers and suppliers from India. The main reason behind that is our continuou ...

VIEW MORE

Rod Threading Machine is a machine that we take pleasure in describing. It is perhaps the best crafted and artistically designed at industrial machinery corporation factory at Ludhiana. We have been i ...

VIEW MORE

We have the wide range of semi-automatic Steel TMT Chaser Rebar Threading Machine which is used for the site projects and it does outside threading on TMT bars. Steel TMT Chaser Rebar Threading Machin ...

VIEW MORE

Electric Conduit Pipe Threading Machine is used to thread the external area of the conduit pipes. IMC Machines highly specialized and can be used solely for industry-specific purposes. There are only ...

VIEW MORE